Properly supporting vegetable-growing activities.

Introducing a lineup of My Mini products providing a huge variety of choices that are

perfect for engaging in a wide array of tasks.

This mini-cultivator is equipped with a new-model GB engine that complies with the third protocol on gas emission controls. This engine is friendly to both users and the environment by virtue of the fact that it further reduces the emission of harmful substances contained in exhaust fumes. Also, all models are outfitted with Miracle Start (*2), a convenient system for easily starting the engine on the first attempt with little effort. An oil bath wet-type cleaner and a mud-blocking cover are also provided as standard features.

The work speed has been set to enable work in narrow places and reversing operations to be safely undertaken.

Each of these mini-cultivators is equipped with a return clutch that enables the clutch to be turned on or off without having to let go of the handle. The side clutch lever imposes only a slight operating load and can be easily operated.

The engine can be immediately stopped in an emergency by pressing a button-type engine-stop switch.

Park easily and safely with the use of a parking brake. (MM708AS)

The height of the handle can be easily set to one of three different levels just by gripping the lever in accordance with the conditions of the work being performed and the height of the user. (Adjustments for the MM458BS are made through a chrysanthemum-shaped knob.)

The handle direction can be easily changed through a one-touch lever-activated process. The left-right positioning of the side clutch can also be automatically reversed.

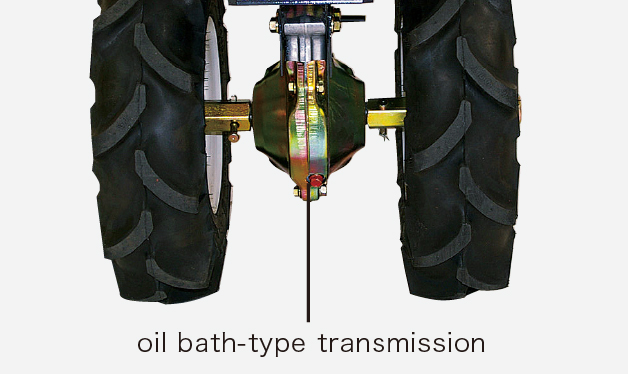

These mini-cultivators feature an oil bath-type transmission capable of accommodating high-load axle operation. A wide range of work conditions can be handled.

Equipped with a large-capacity 2.8 L fuel tank, these mini-cultivators feature a fuel system that allows the amount of remaining fuel to be ascertained at a glance. The cap for the fuel tank is large and easy to grip.

■ Six forward gears and two reverse gears

MM458BS/MM558AS/MM658AS

■ Four forward gears and two reverse gears

MM708AS

An angle rotor is effective for turning over the soil (plowing to replace surface soil with subsoil) and tends to be resistant to the entwining of grass and weeds.

■ MM458BS・558AS・658AS Code No.31305 10930

■ MM708AS Code No.31305 10761

The deep-tilling Miracle Rotor employs a special tine form for better penetration of the soil. Highly capable of breaking apart soil, this rotor can be used to engage in deep-tilling work to a depth of approximately thirty-five centimeters.

■ MM458BS・558AS・658AS Code No.31307 11840

■ MM708AS Code No.31307 12060

Code No.31324 20130

Code No.31351 10060

Code No.31256 90020

Code No.31256 30020

Code No.31256 30310

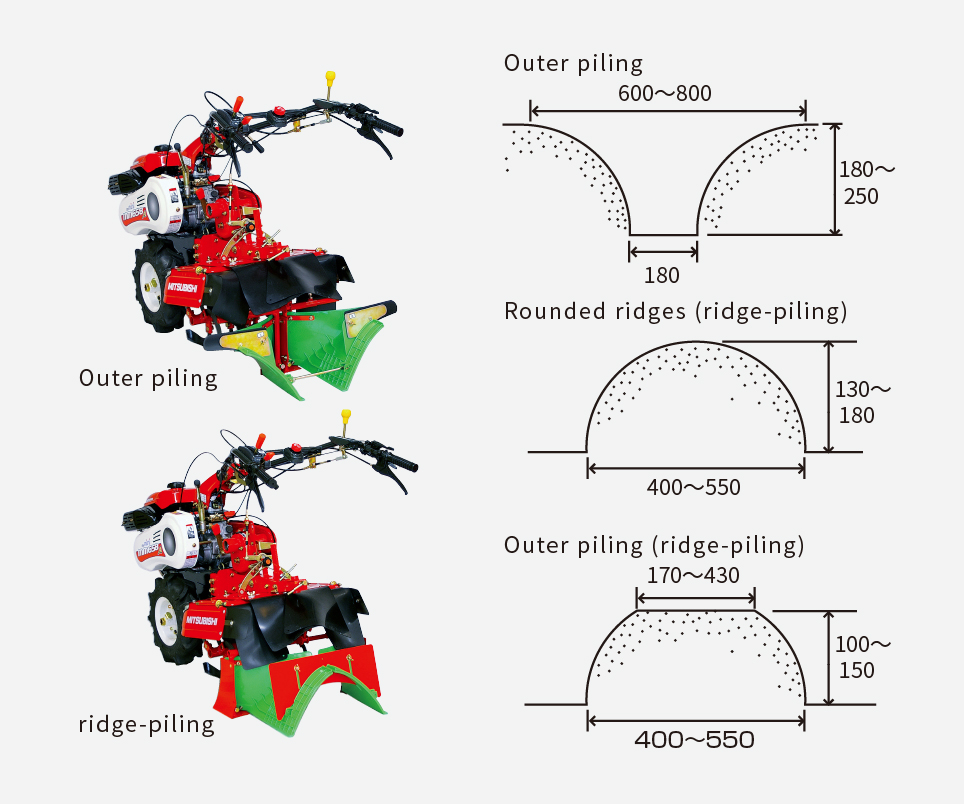

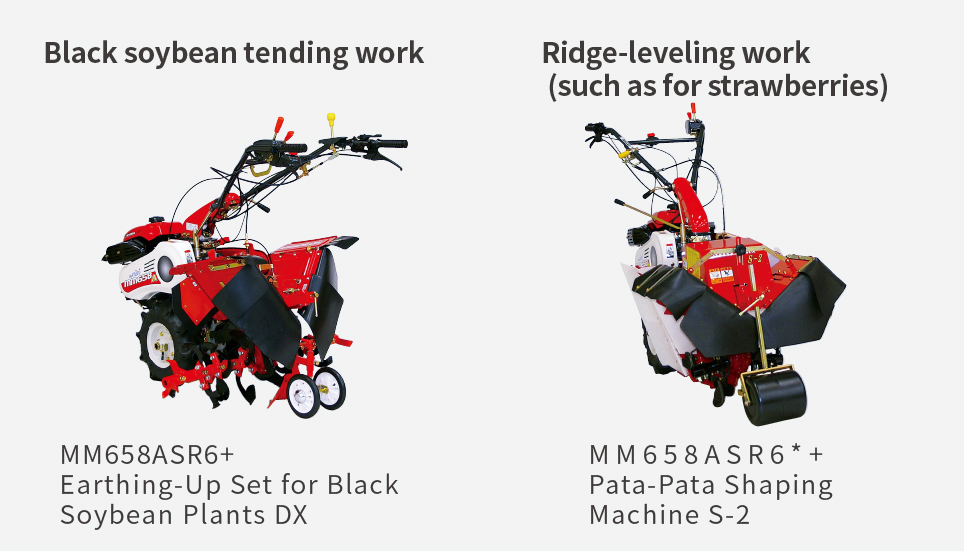

Two kinds of work—inner piling and outer-piling—can be performed

by reconfiguring this attachment.

For cultivate rotary shafts Code No.31343 10990

For cultivate rotary shafts Code No.31341 11840

For traction Code No.31341 11850

For cultivate rotary shafts Code No.31341 10541

For traction Code No.31341 10551

For cultivate rotary shafts Code No.31343 10341

For traction Code No.31343 10281

For cultivate rotary shafts Code No.31350 40230

For traction Code No.31350 40220

For cultivate rotary shafts Code No.31350 30460

For traction Code No.31350 30470

Code No.31256 35078

Code No.31434 30510*

You will need to change the wheel tubes and tires.

Keep the following four points in mind when utilizing aridger, furrow-scooping device, or ridge builder in conjunction with the rotary shaft:

(i) Be sure to make adjustments in such a way that the rotary tine and attachment will not come in contact with one another.

(ii) Assume that the attachment will descend by only the depth tilled by the rotary shaft (approximately 5 to 10 centimeters) and adjust accordingly.

(iii) The leading edge of the attachment (plowshare) should be positioned approximately 1 to 3 centimeters above the plow sole.

(iv) If the attachment has a tail wheel, adjust the distance between the underside of the attachment and the protruding parts of the tail wheel to between approximately 1 and 2 centimeters.

*For pull-type wing hillers and furrow-scooping devices, a separate type-95 universal hitch (code no. 31114 40080) is required.