Mitsubishi Agricultural Machinery

Making machineries and form a connection

with people for over a century.

We have sought to continuously operate as an agricultural engineering company capable of providing the market with proprietary technologies developed with respect for tools and feedback from customers.

We produce tools and exert every possible effort to engage in agricultural pursuits together with our customers. Making history is what we at Mitsubishi Mahindra Agricultural Machinery Co., Ltd., have always done to date and will continue to do as we go forward.

Chujiro Sato 1887–1944

Chujiro Sato 1887–1944

Founder / Chujiro Sato was born on January 11, 1887, in Adakae, Higashi-Izumo Town, Shimane Prefecture (in what is now Matsue City).

As the founder of Sato Machinery (presently Mitsubishi Mahindra Agricultural Machinery), Chujiro Sato is known as the father of agricultural machinery (inventor). In his youth, he once rode his bicycle alongside a rice field when he was caught in a crater and fell. Upon seeing how the wheels were turning sideways, he invented the Sato rice and grain thresher, a rotary rice thresher. Chujiro Sato went on to engage in extensive research and invented numerous types of farming equipment and tools. By cultivating markets in not just Japan but throughout Asia, the profile of Sato-branded agricultural machinery rose nationwide.Chujiro Sato left behind a great legacy not just as a businessman but also as a town mayor thanks to the positive impact he had on local development.After the death of Chujiro Sato, a bronze statue of the founder was placed in a small park next to the head office of the company to satisfy the desires of many who wished to commemorate his remarkable life.

Tractor GS202

Tractor GS202

In 1959, the YB80, Sato Machinery’s first small tractor, appeared on the scene. With the arrival of the 1970s, the demand for a tractor offering greater power output which resulted in the emergence of a lineup of mid-class tractors included the ST2500 (D2500). In 1981, the company released the industry’s first flat-deck model that allowed the operator to place the feet flat on the deck. In 1985, the F1 Series of tractors, which incorporated MAC which microcomputer control system, was released to the market. In 2003, the company introduced GCR160, a 160-horse power full-crawler tractor.In 2012, a model equipped with a gyro-MAC system to enable high-precision cultivation made its debut. In 2017, the company unveiled the small tractor GS Series, which featured the new Eagle Design for Mitsubishi tractors. Research is being undertaken daily to ensure that each Mitsubishi tractor can have a long life thanks to the pursuit of task performance, safety, and durability.

Small Axial-flow combine VCH750

Small Axial-flow combine VCH750

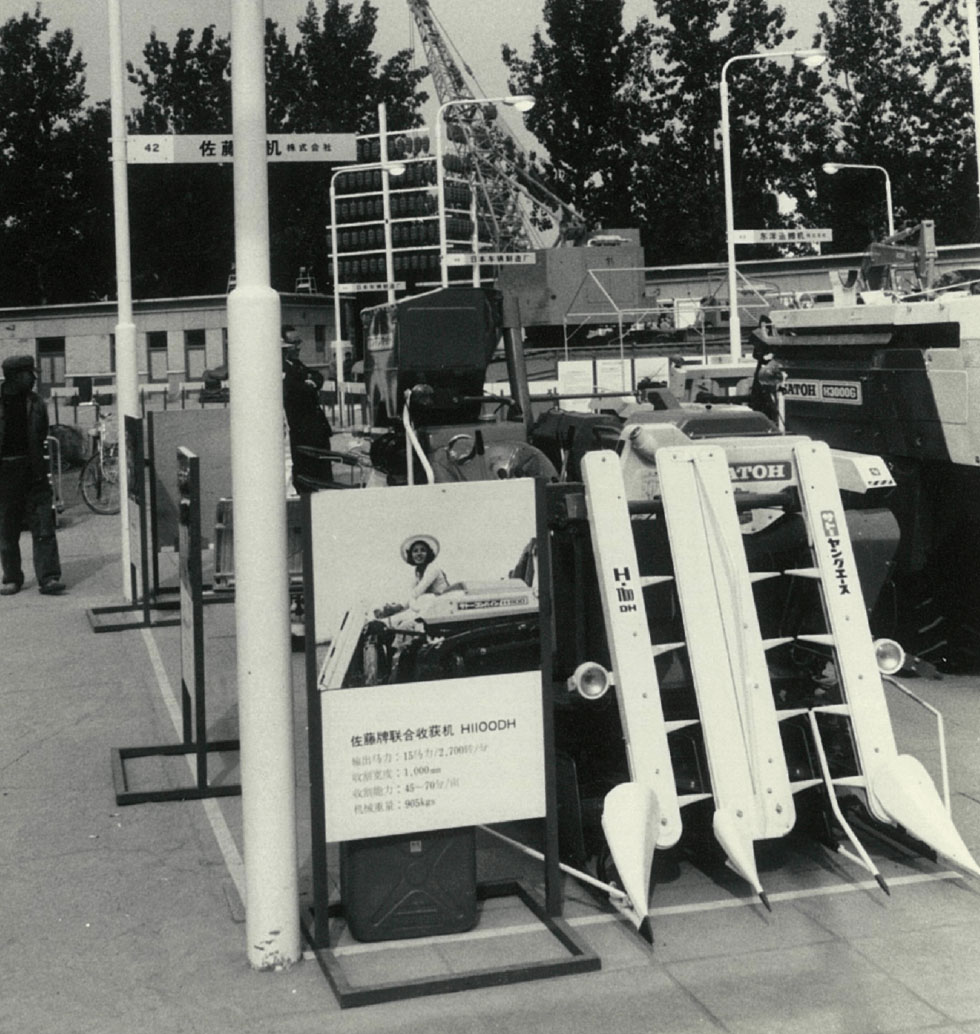

In 1968, fifty-four years after the invention of the Sato rice and grain thresher in 1914, Model H50, the industry’s first rideable head feeding combine, was introduced. Twin step-up threshers, component-up features (1995), and other proprietary functions have long been incorporated into many models offered by the company. In 2002, VM7, the world’s smallest combine, was released to the market. We commercialized the Super e-Thresher in 2010 and the VCH650, Japan’s smallest Axial-flow combine, in 2012; both were the result of joint research conducted with the current National Agriculture and Food Research Organization. The philosophy behind the Sato rice and grain thresher remains just as valid today and has been inherited by modern combines produced by the company.

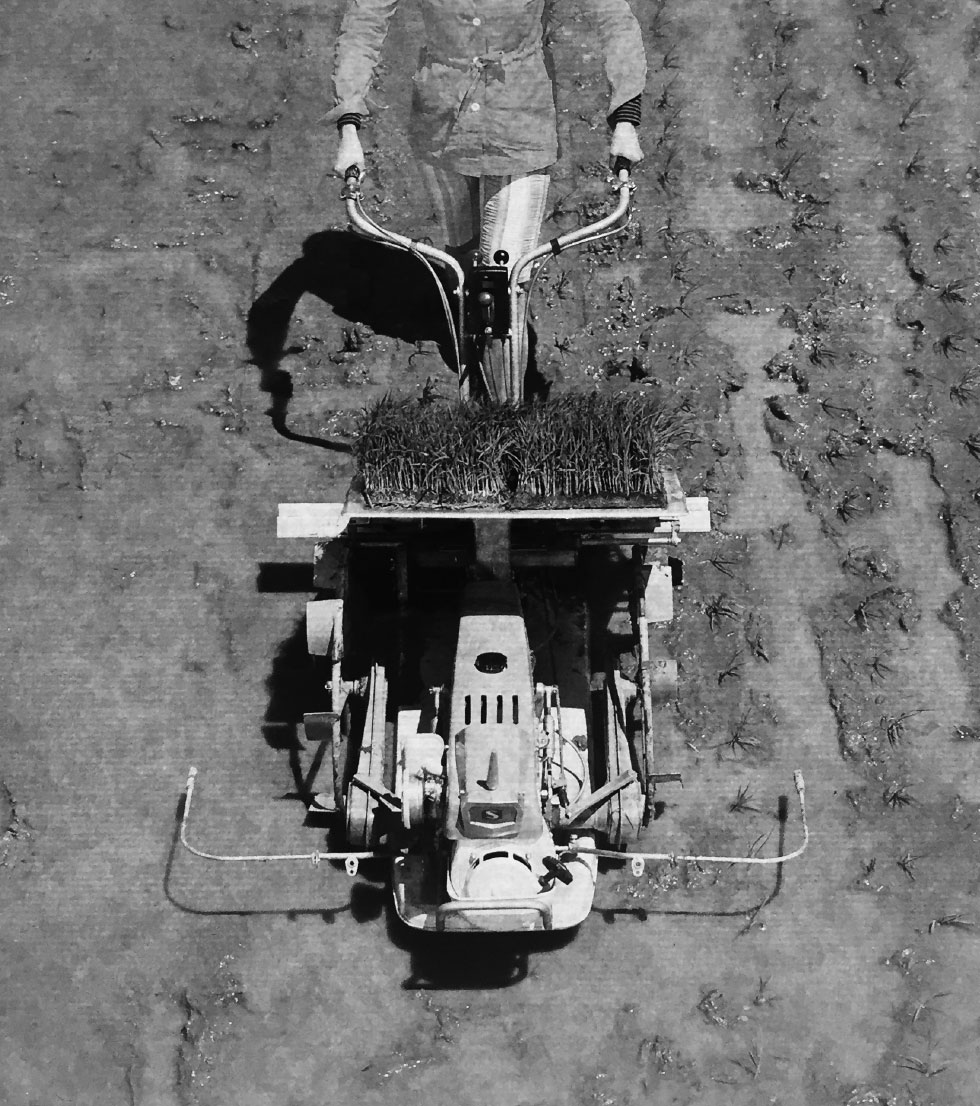

In 1976, we developed a side-row pasting system to enable environmentally friendly high-precision fertilization to be carried out at the same time as the transplantation of rice. We were the first in the industry to develop this and many other laborsaving technological innovations tied to rice transplantation. We have made many labor-saving contributions in this area by, among other actions, developing “Quick Rice Trans-planter” that works without having to till the ground, “Harrow Rice Trans-planter” that transplants nursery at the same time that rotary harrowing is undertaken, and a recycled paper-mulching rice trans-planter designed to reduce the amount of weeding carried out by organic farmers. In 2002, we released “Makurakko”, a headland-leveling device used to eliminate what was once hard labor by coupling it with our harrow rice trans-planter. In 2006, we developed a nursery bed slider that was designed to help reduce the amount of heavy labor involved in feeding seedlings to the trans-planter. We intend to continue to help achieve superior laborsaving results for enhanced task performance.

Mini-Tiller MMR600A

Mini-Tiller MMR600A

Power tillers and cultivators constituted the essence of cultivation work since before the arrival of tractors on the farming scene. They are put to a wide variety of different uses, including the cultivation of everything from paddy to vegetables-field, and remain a part of numerous crop systems today. In 1988, we released the My Boy MMR50, the first rear rotary-type Mini-tiller in the industry, and effectively established a new product category. In 2005, the front rotary type Mini-Tiller MFR3 was introduced for easier, more user-friendly operations. The latter half of the first decade of this century saw a home-gardening boom that prompted us to release EL20, the first mini-cultivator to run on a cartridge-gas in the industry, in 2009. We will continue to provide the products that are ideal for many crop-cultivation systems in an effort to bolster safe, reliable Japanese-style crop farming in line with the rising levels of consumer interest in food.

| June 1914 | The Sato Trading Company is established and the company commences the manufacturing and selling of rotary rice threshers. |

|---|---|

| February 1954 | The name of the company is changed to Sato Machinery Co., Ltd. |

| September 1959 | The Sendai Plant is established in Tagajo City, Miyagi Prefecture; the company commences the manufacturing of tractors. |

| May 1968 | The industry’s first rideable head feeding combine harvester is released. |

| April 1971 | Mitsubishi Machinery Sales Co., Ltd., is established through a merger with a sales company. |

| March 1976 | The industry’s first rice transplanter equipped with a side-row pasting system to enable fertilization to be carried out at the same time as the transplantation of rice is introduced. |

| February 1980 | With Sato Machinery Co., Ltd., as the surviving corporation, the company undergoes a merger of equals with Mitsubishi Machinery Sales Co., Ltd., and changes its name to Mitsubishi Agricultural Machinery Co., Ltd. |

| June 1981 | The company releases PALCEED series tractor MT2201/2501, the industry’s first flat-deck tractor. |

| June 1988 | My Boy MMR50, a rear rotary-type Mini-tiller, is introduced to the market. |

| June 1994 | MHP6H, a Makurakko-branded forward-type harrow rice trans-planter, is released. |

| October 1995 | MC320, a combine harvester equipped with proprietary twin threshers and component-up features, is introduced. |

| June 1997 | The company introduces MKP505, a recycled paper-mulching rice trans-planter. |

| June 2002 | The company releases the MPR610, which is equipped with “Makurakko”, the industry’s first headland-leveling device to be utilized in this manner. |

| June 2002 | The company releases VM7, the world’s smallest, lightest combine harvester. |

| July 2003 | An OEM contract is concluded with Mahindra USA whereupon the supplying of tractors is commenced. |

| June 2006 | The company releases LV63, which is equipped with an industry-first nursery-bed slider for feeding seedlings to the trans-planter. |

| January 2007 | The sales company is restructured into the East Japan Mitsubishi Agricultural Machinery Sales Company and West Japan Mitsubishi Agricultural Machinery Sales Company. |

| January 2009 | The company introduces “Eco-Latte series” of units constituting the first mini-cultivator to run on a cartridge-gas source in the industry. |

| January 2012 | Production operations are restructured into Ryono Factory Co., Ltd. |

| March 2012 | The company releases VCH650, the industry’s first small axial-flow combine harvester. |

| April 2014 | The sales company is restructured into the Mitsubishi Agricultural Machinery Sales Co., Ltd. |

| October 2015 | The company name is changed to Mitsubishi Mahindra Agricultural Machinery Co., Ltd. |