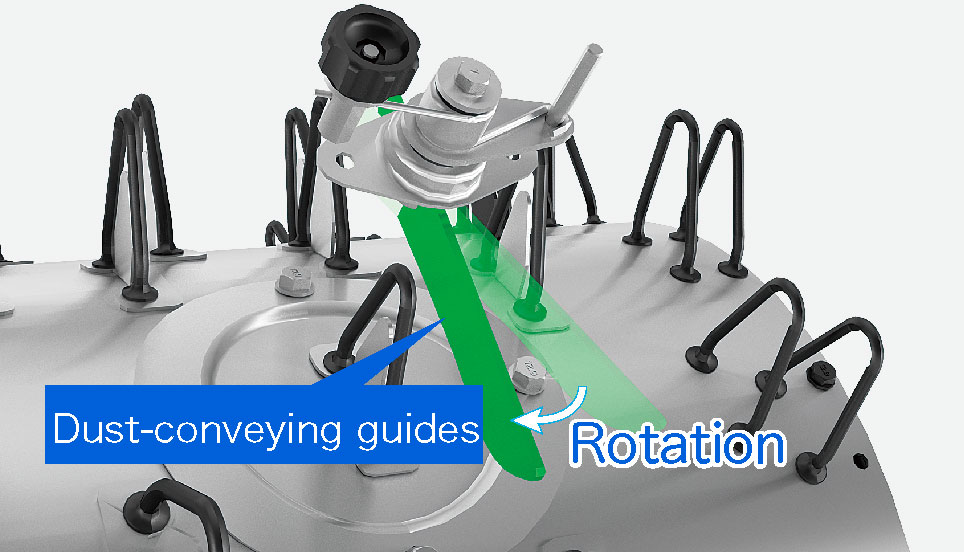

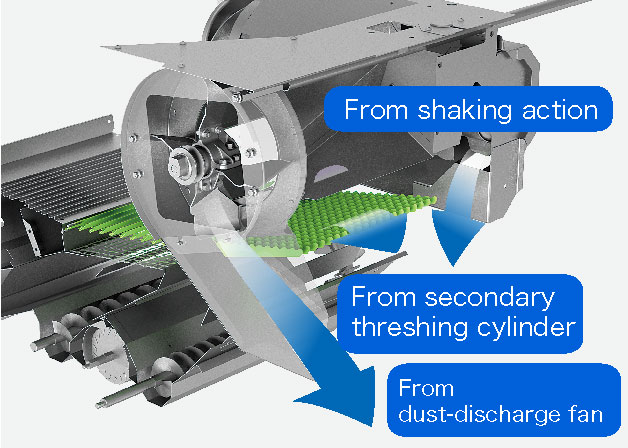

The dust-conveying guides adjust automatically. Without

having to carry out burdensome adjustment operations, stable

threshing performance is achieved by optimally maintaining

the threshing load in the threshing chamber.

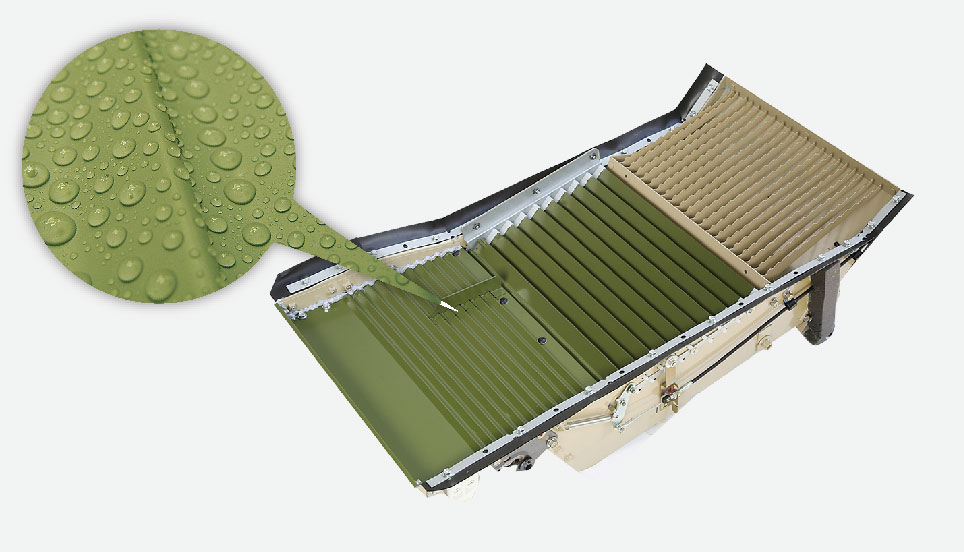

A shaking-flow plate coated in a fluorocarbon resin is used to bolster the slip characteristics and dispersibility of grains and improve adaptability to wet materials and sorting efficiency.

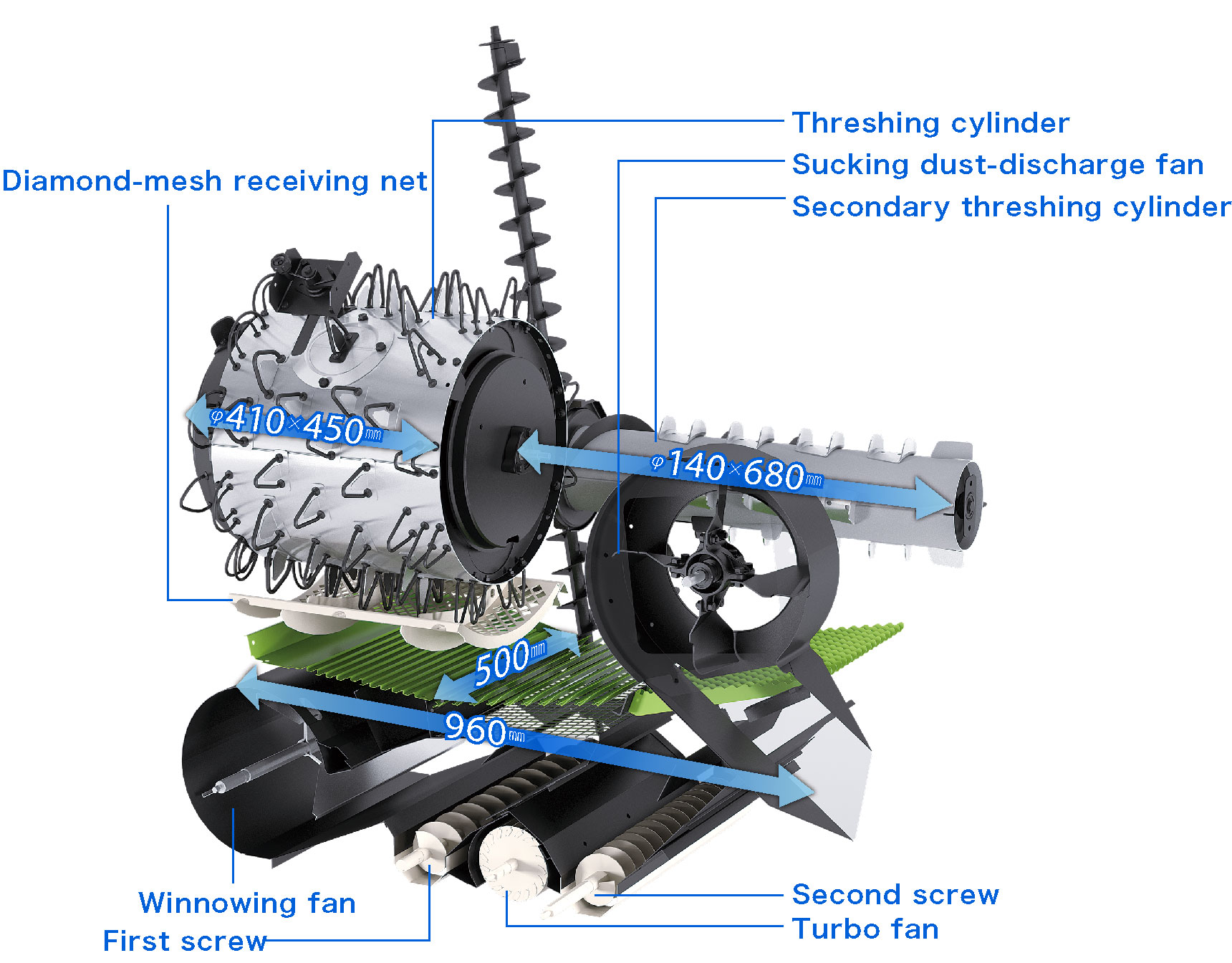

Each of our combines is equipped with a threshing cylinder and secondary threshing cylinder to enable highly efficient, high-precision threshing.

Equipped with a large-displacement three-cylinder diesel engine. Despite its compact size, the engine is high powered enough to perform effectively without difficulty.

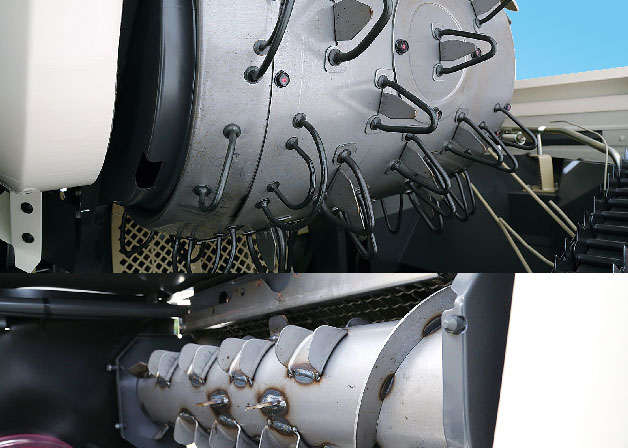

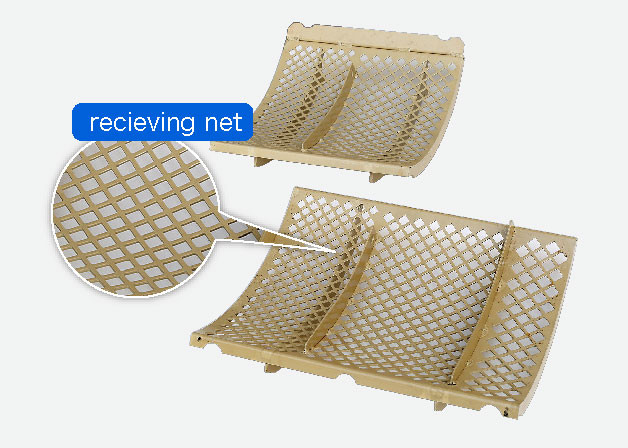

Promotes threshing with Mitsubishi’s original hole shape. With less stucking hole, this net is also easy to clean.