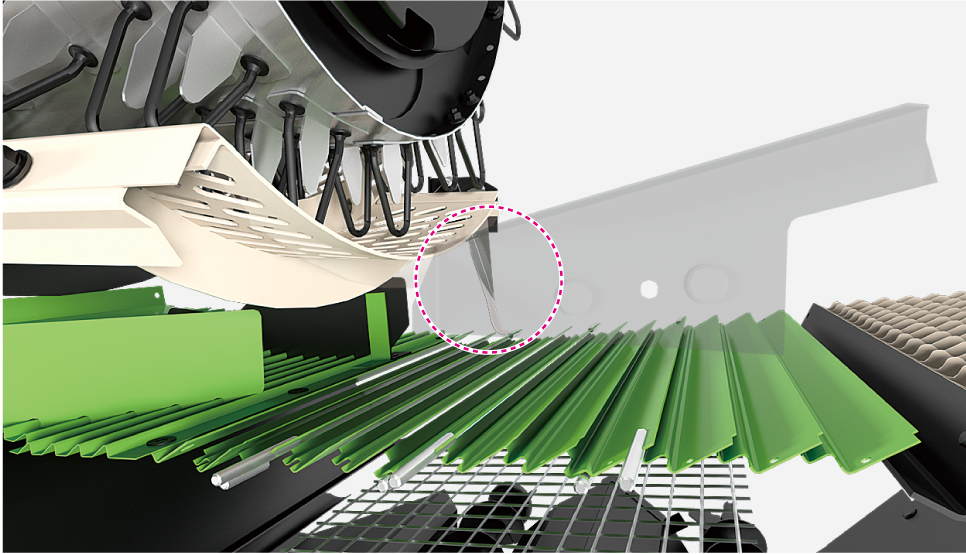

Promotes threshing with Mitsubishi’s original hole shape. With less stucking hole, this net is easy to remove and install without the use of tools as well as to clean.

The amount of crop on the Rocking-flow plate is detected with floating sensors. Fin openings are then adjusted according to the amount of crop to be sorted in order to facilitate careful sorting.

A Rocking-flow plate coated in a fluorocarbon resin is used to bolster the slip characteristics and dispersibility of grains and improve adaptability to wet materials and sorting efficiency.

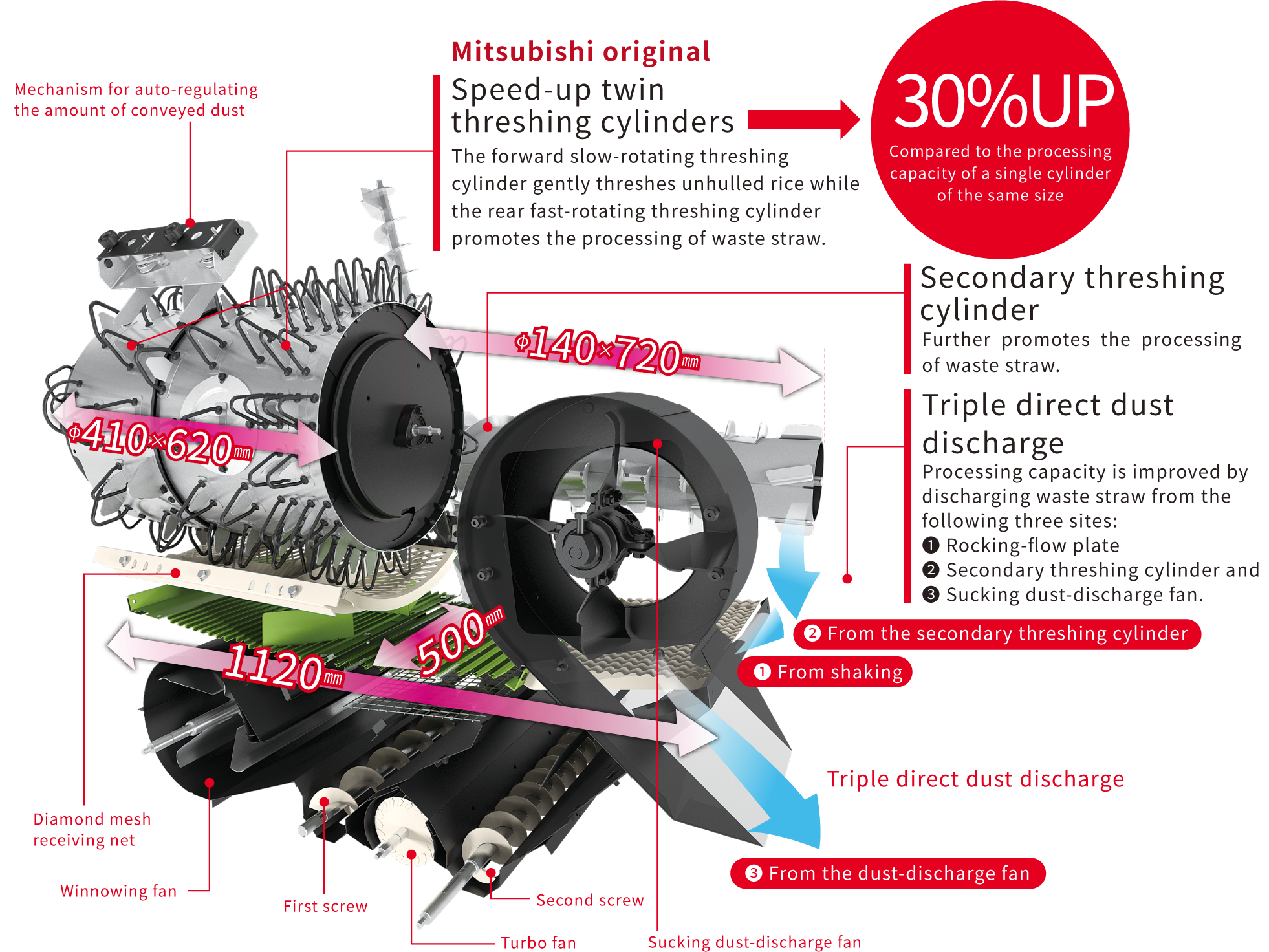

The dust-conveying guides adjust automatically. Without having to carry out annoying adjustment operations, stable threshing performance is achieved by optimally maintaining the threshing load in the threshing chamber.

By feeding airflow for sorting that has been stabilized with a second dedicated airflow for sorting and an airflow for winnowing, sorting precision and processing capacity are enhanced.