The first and second screw covers and secondary cylinder cover can be removed and installed without the use of tools.

The receiving net can be easily removed and installed without the use of tools. Since the latticework is formed with a die-cutting process, the net itself is light and easy to clean.

Easily open and close the auger screw cover without the use of tools.

The undercarriage of the combine can be easily washed.

The base plate for the first and second screws can be easily opened with a single lever.

All relevant parts can be lubricated with just the press of a button.

Can easily check the contamination of water into the fuel.

The workload imposed by fueling is lessened since fueling can be done by putting fuel can on the stand.

The raising cover can be easily removed and installed since it is fastened from the front with a knob bolt.

Hydraulic electronic components can be easily checked and any problems that are detected can be promptly addressed.

Crawler rollers with grease nipples that help facilitate maintenance functions have been adopted.

The cutting blades can be exposed to facilitate maintenance. Both the upper set and lower set of cutting blades can be adjusted.

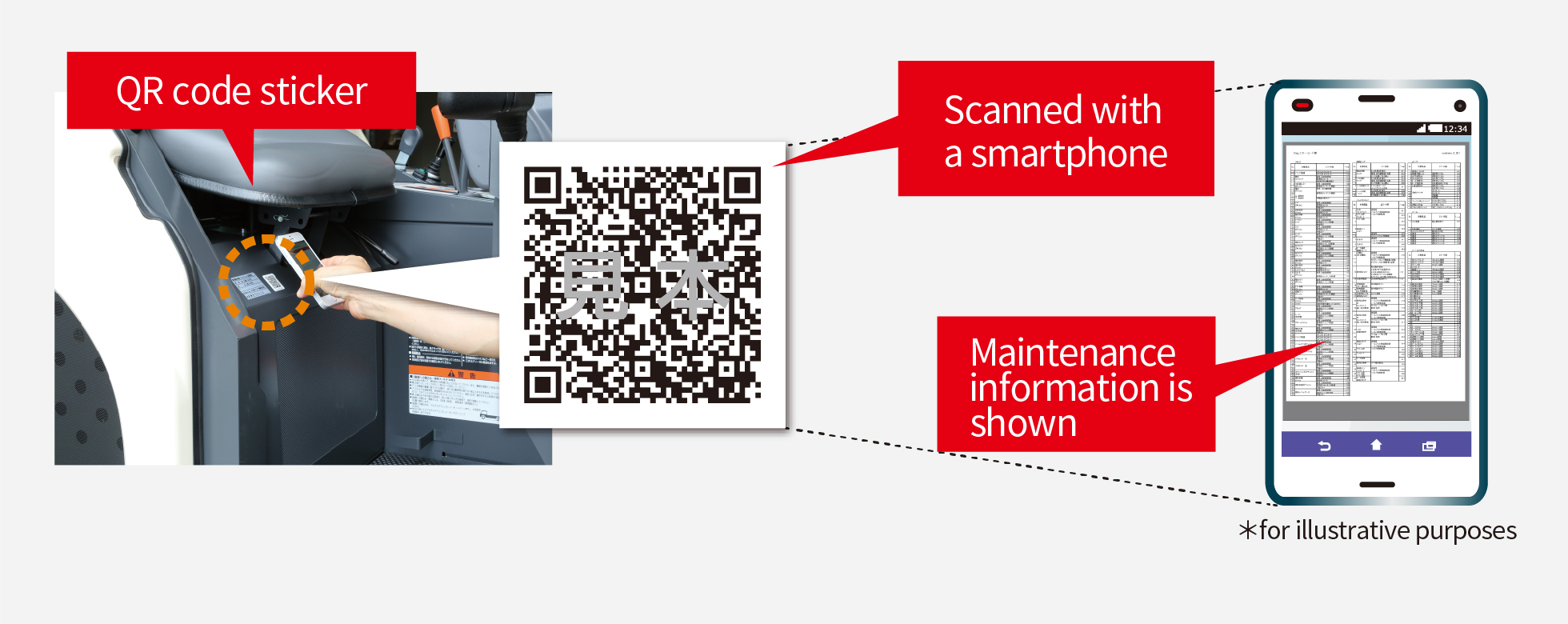

Scan the QR code affixed to the combine with your smartphone or other such device to access all sorts of information on maintenance on your screen.

"- List of error codes

- List of consumables (engine-related items and items relating to belts, tines, cutters, and cutting/scythe blades)

*A QR code reader (app) is required. *Packet charges incurred when scanning the QR code are assumed by the operator."

A measuring ruler has been added to a belt listing label. Can be used in place of a measuring instrument when adjusting the belt set or gap measurements.

SP-S323W(double for the V335)

SP-S323TQ(third for the V335)

SP-Y433W(double for the V435)

SP-Y433TQ(third for the V435)

part no. 3599 4521 000

※other parts required.

Model DMS28S-KIT

Model K-VY434S

Model KN-S333

Model DC-VM219Y433

part no:3598 9750 000

Model K-RCVSVCH

Model K-V435DF

part no:3667 9700 000

Model CH333

part no:3669 9904 000

※other parts required.

part no:3669 9904 000

※other parts required.

part no:3596 3035 000

※other parts required

part no:3565 2254 000

part no:3578 2301 002

part no:3578 2311 002

part no:3599 2555 000

separate mounting parts required

| Product name | Model | Handling category |

Comment | V335 | V435 | |

|---|---|---|---|---|---|---|

Reaping part |

Super divider | SP-S323W | Main body |

One-touch installation and removal, automatic chain tensioner (double) | ◯ | ‐ |

| Super divider | SP-S323TQ | Main body |

One-touch installation and removal, automatic chain tensioner (third) | ◯ | ‐ | |

| Super divider | SP-Y433W | Main body |

One-touch installation and removal, automatic chain tensioner (double) | ‐ | ◯ | |

| Super divider | SP-Y433TQ | Main body |

One-touch installation and removal, automatic chain tensioner (third) | ‐ | ◯ | |

| Narrow guide(Right) | Part | Part no. (3599 4521 000) Standard equipment for V335 ※other parts required. |

‐ | ◯ | ||

Driving operations part |

Dust control cover kit | DC-VM219Y433 | Main body |

2-steps open and shut function | ◯ | |

| Automatic direction kit | Part | Part no. (3598 9750 000) | ◯ | |||

| Wireless remote control for the auger | K-RCVSVCH | Main body |

Motorized clutch + auger flap kit (K-V435DF) required. | ◯ | ||

| Motorized clutch + auger flaps | K-V435DF | Main body |

◯ | |||

| External parking brake kit | Part | Part no. (3667 9700 000) | ◯ | |||

| Combine hood | CH333 | Work equipment | Work equipment code (31804 10427) | ◯ | ||

| Work light (auger tip) | Part | Part no.(3669 9904 000)Lamp ASSY、 3669 9903 000 Harness G、 3586 9395 000 plate)※other parts required. |

◯ | |||

| Work light (enterance of the threshing part) | Part | ◯ | ||||

| Work light (left side of the reaping part) | Part | Part no.(3596 3035 000) ※other parts required. |

◯ | |||

Cutter part |

Short-cutting cutter kit | DMS28S-KIT | Main body |

For M specifications | ◯ | |

| Diffusion screw kit | K-VY434S | Main body |

For V435 specifications (Unsuitable for V335) | ‐ | ◯ | |

| Slide knotter | KN-S333 | Main body |

Ear and plant base bundle type | ◯ | ||

| Knotter dropper | D-KN-S1 | Main body |

Equip to KN-S333 | ◯ | ||

| Bale-standing device | R-KSMS20 | Main body |

Chain-conveyance system | ◯ | ||

| Installation kit | R-VS281 | Main body |

KN-S333 (Need to equip) | ◯ | ||

| Cutter dropper | S-S333D | Main body |

Collection plate, spring-based system | ◯ | ||

Traveling part |

Oil bath-type tank roller ASSY | Part | Part no. (3565 2251 000) (6 units required.) | ◯ | ||

| Oil bath-type Idler L ASSY | Part | Part no. (3578 2301 002) (1 unit required.) | ◯ | |||

| Oil bath-type Idler R ASSY | Part | Part no. (3578 2311 002) (1 unit required.) | ◯ | |||

| Rear weight | Part | Part no. (3599 2555 000) ※other parts required. |

‐ | ◯ | ||