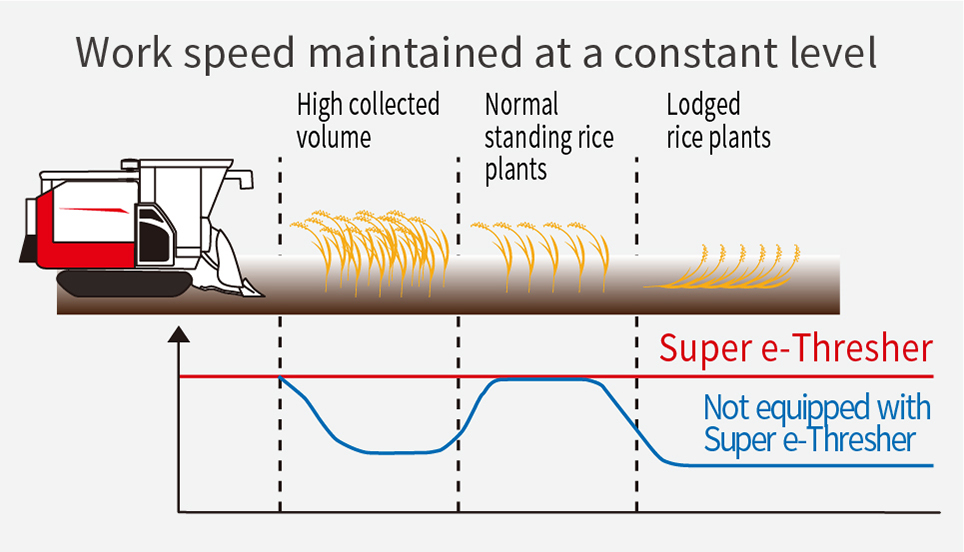

Core threshing technology supporting high levels of efficiency and precision

With the V6120, it is now possible to achieve higher-order threshing performance and a 2.0

m/s high-speed rate of reaping.

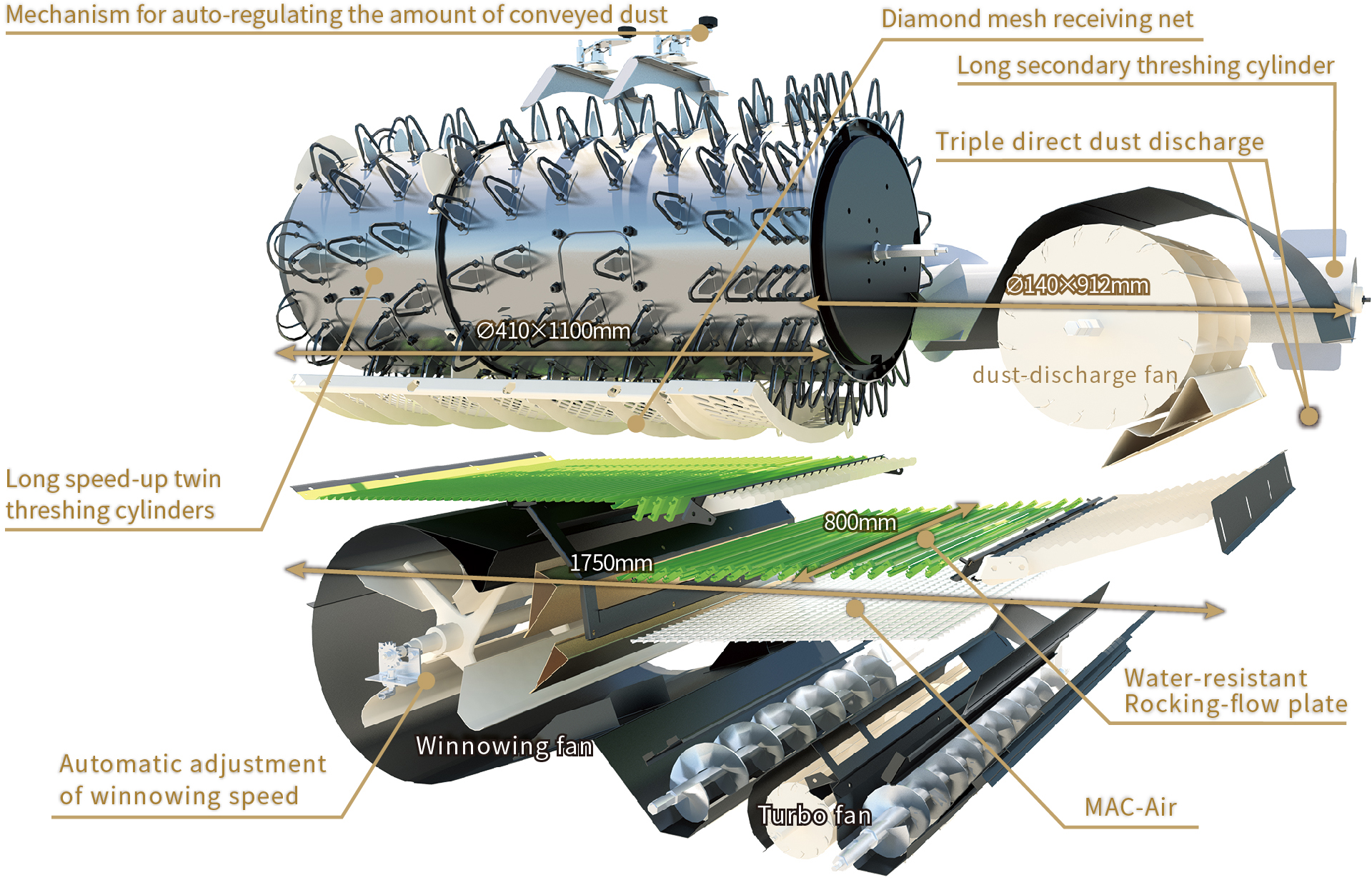

The core part of the threshing system features speed-up twin threshing cylinders boasting exceptional work efficiency. The forward slow-rotating threshing cylinder gently threshes crop while the rear cylinder rotates quickly to process any rice that remains crop and waste straw. In this way, the speed-up twin threshing cylinders boost capacity by approximately 30 percent over single cylinders of the same size (as found in other models we sell). By also equipping the combine with a 912-millimeter-long secondary threshing cylinder, the processing of waste straw is promoted and high-precision threshing is realized.

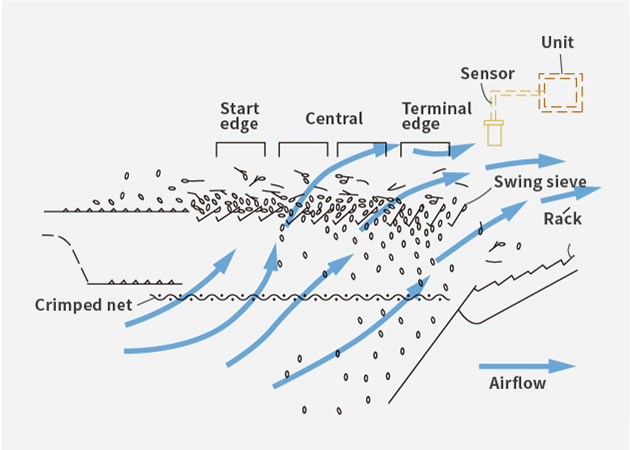

The amount of airflow for sorting is automatically adjusted according to the amount of crop to be processed. Sorting precision when engaging in high-efficiency work is further improved. When engaging in manual threshing, the amount of unhulled rice that is processed is low. For this reason, airflow is reduced to suppress third-stage dispersion.

*1: The percentage of waste straw included in first-stage collected matter is compared to prior model VR6108.

*2: The percentage of grain included in third-stage discharged matter when engaging in manual threshing of a certain amount is compared to prior model VR6108.

Promotes the threshing of crop with Mitsubishi’s original hole shape. With less clogging taking place, this net is also easy to clean.

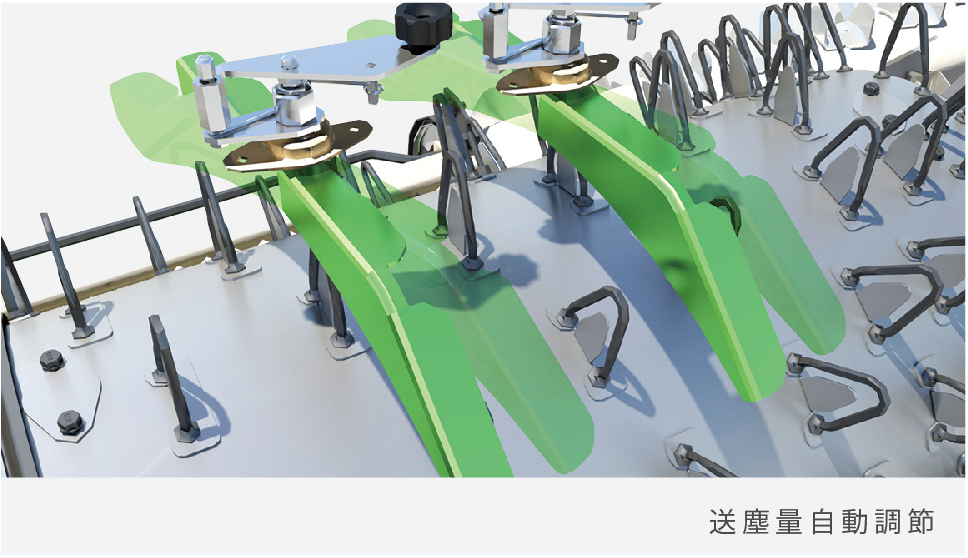

Sorting fins are subject to fully automatic control based on air-based detection within the threshing process to enable high-precision sorting.

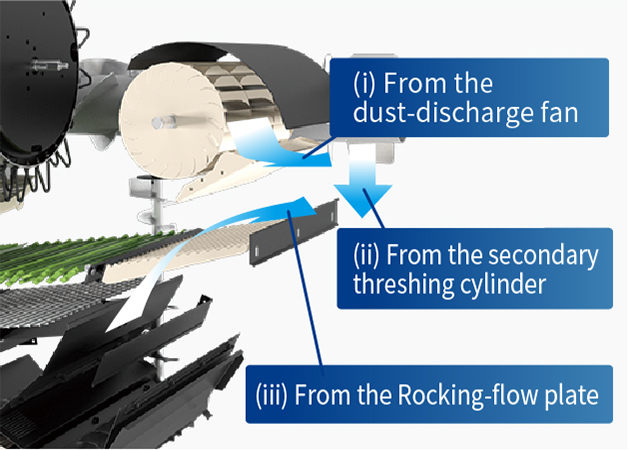

Waste straw is directly discharged from three different sites on the combine. With little waste retained, exceptional processing capacity is maintained at all times even under harsh conditions.

The dust-conveying guides adjust automatically. Without having to carry out burdensome adjustment operations, stable threshing performance is achieved by optimally maintaining the threshing load in the threshing chamber.

A Rocking-flow plate coated in a fluorocarbon resin is used to bolster the slip characteristics and dispersibility of grains and improve adaptability to wet materials and sorting efficiency.