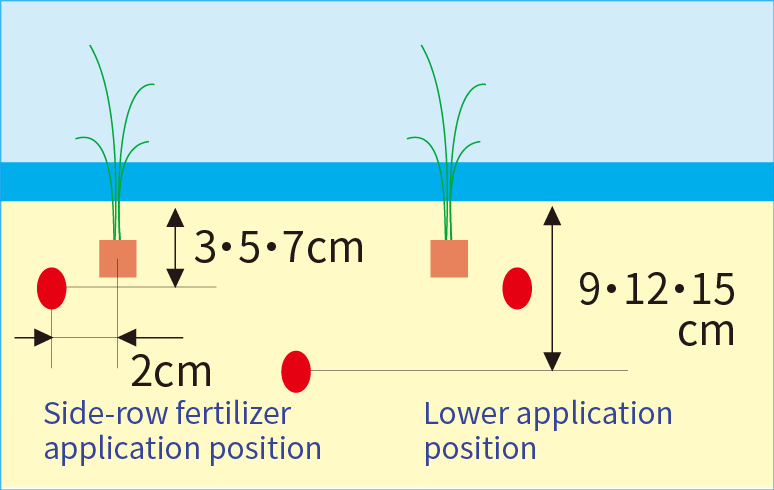

The paste fertilizer application system (side-row fertilizer application system) that is used with these models enables effective application of fertilizer by way of the configuration of fertilizer-application positioning and volume at high levels of precision. Dual-stage paste fertilizer application system promotes a greater fertilizer response through the use of a slow-release paste fertilizer, which in turn produces a labor-saving benefit by reducing the need to apply additional fertilizer at a later date.

Positions corresponding to

dual-stage application of paste fertilizer

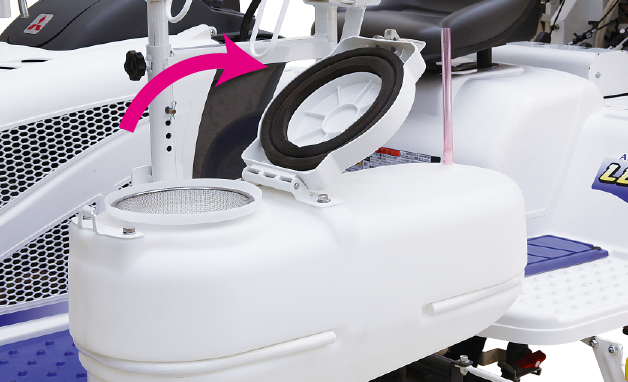

Thanks to large-capacity ank, it reduces frequency to be replenished with fresh fertilizer and helps operators engage in uninterrupted work. As the tank is mounted externally, the rice transplanter itself will sustain less staining by paste in the course of operations. The cover can be easily opened through a one-touch process.

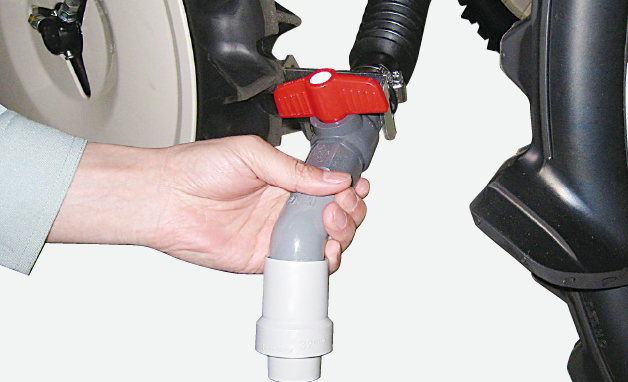

A handy paste drain cock allows you to discharge fertilizer easily without getting your hands dirty.

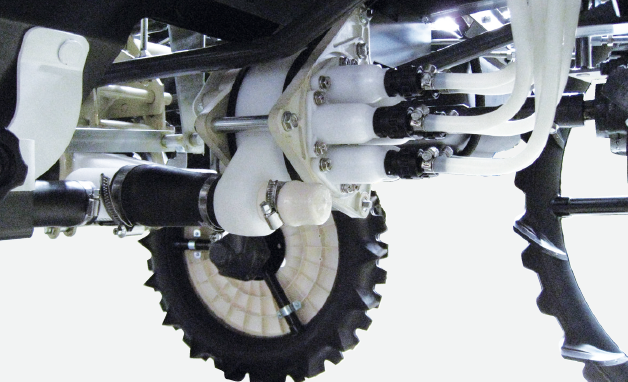

As the paste pump is embedded in the driving unit, rusting caused by mud or fertilizer is unlikely and maintenance costs can be reduced.

Superior durability has been achieved by utilizing rust-proof materials for everything from the hooks to the bolts that are used for the paste feeder in order to prevent rusting caused by exposure to fertilizer.

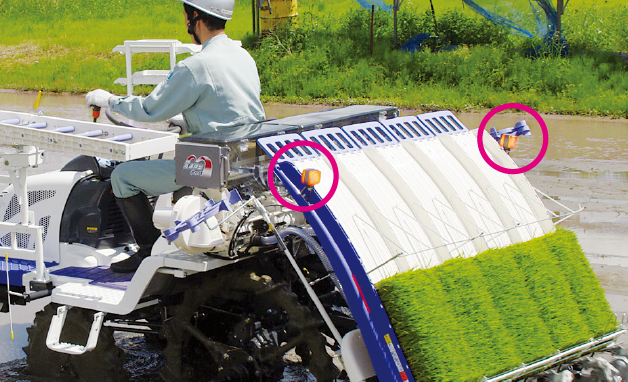

The left and right indicators will flash once machine is out of fertilizer. Remotely located assistant can also be notified to increase efficiency of any assistance work that is undertaken.

Large-capacity hopper enables uninterrupted work to be performed without replenishing fertilizer in addition. Height of hopper has been reduced, and it contributes to improve operating performance whenever hopper is being replenished and rear-facing visibility from the driver.

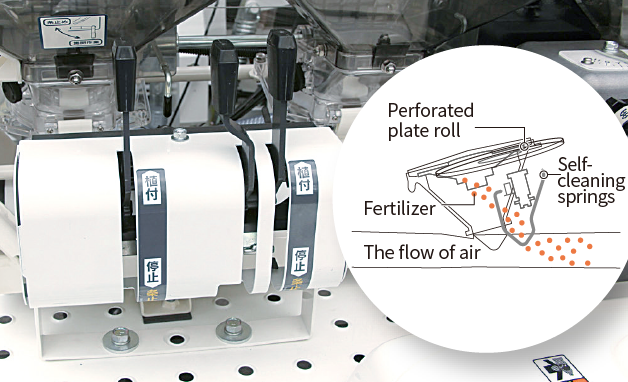

Flip-up hopper can be quickly emptied of any remaining fertilizer by opening outlet on either side. Perforated plate can also be cleaned with ease.

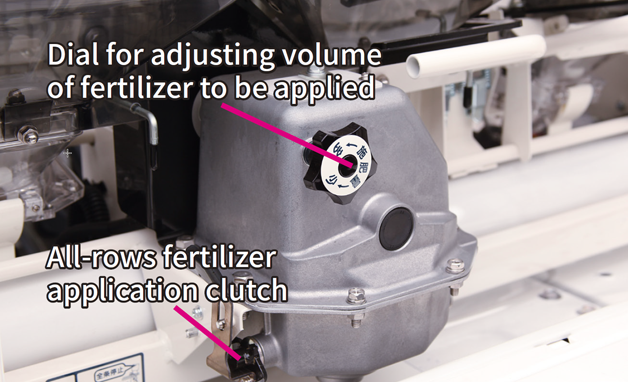

The volume of fertilizer to be applied can be easily adjusted with a single dial. Adjustments between ten and ninety kilograms per tenth of a hectare can be made with a complete seedling count. An all-rows fertilizer application clutch is also provided to enable driving and blower to be shut-off through a one-touch process whenever the fertilizer is not being applied.

Faulty operations are prevented since the fertilizing row-stop clutch and planting row-stop clutch are linked. Self-cleaning springs prevent clogging of air-merging parts where granulated fertilizer is susceptible to pooling and facilitates the distribution of fertilizer.

Left and right indicators will flash once machine is out of fertilizer. Remotely located assistant can also be notified to increase efficiency of any assistance work that is undertaken.