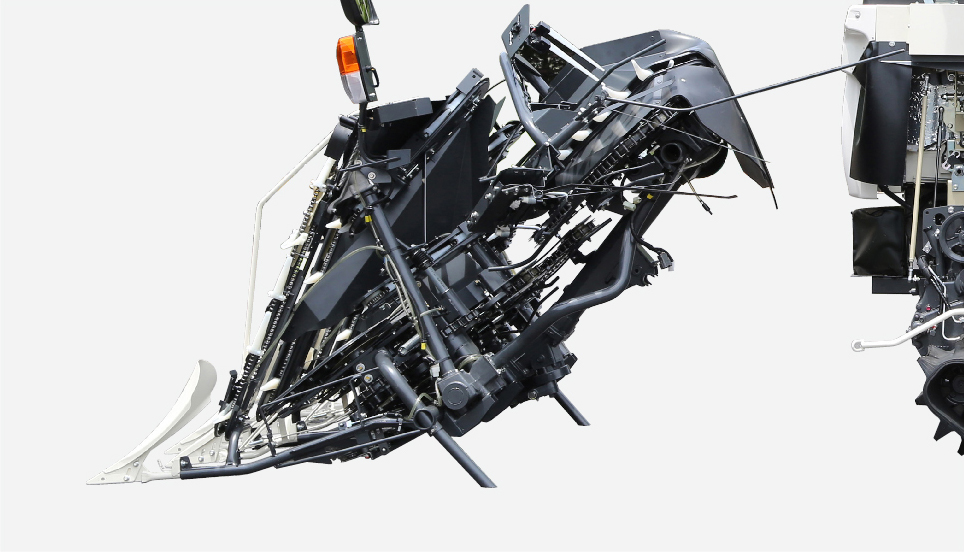

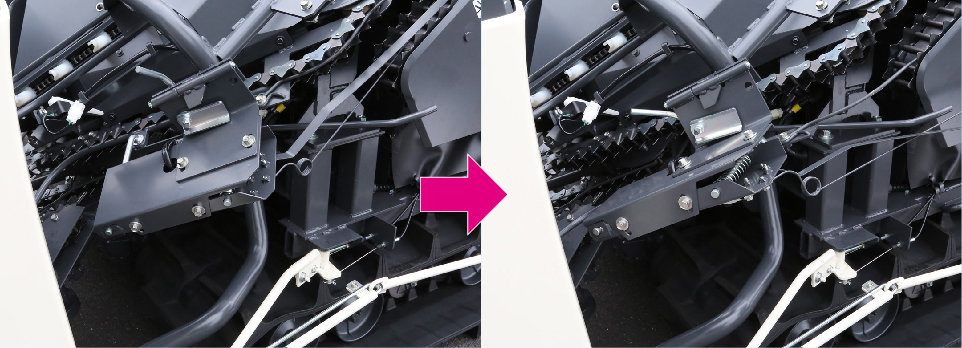

The combine is equipped with a reaping stand as a standard feature. The reaping part can be removed and installed in a stable state whenever maintenance work is undertaken. The reaping stand is installed under the battery.

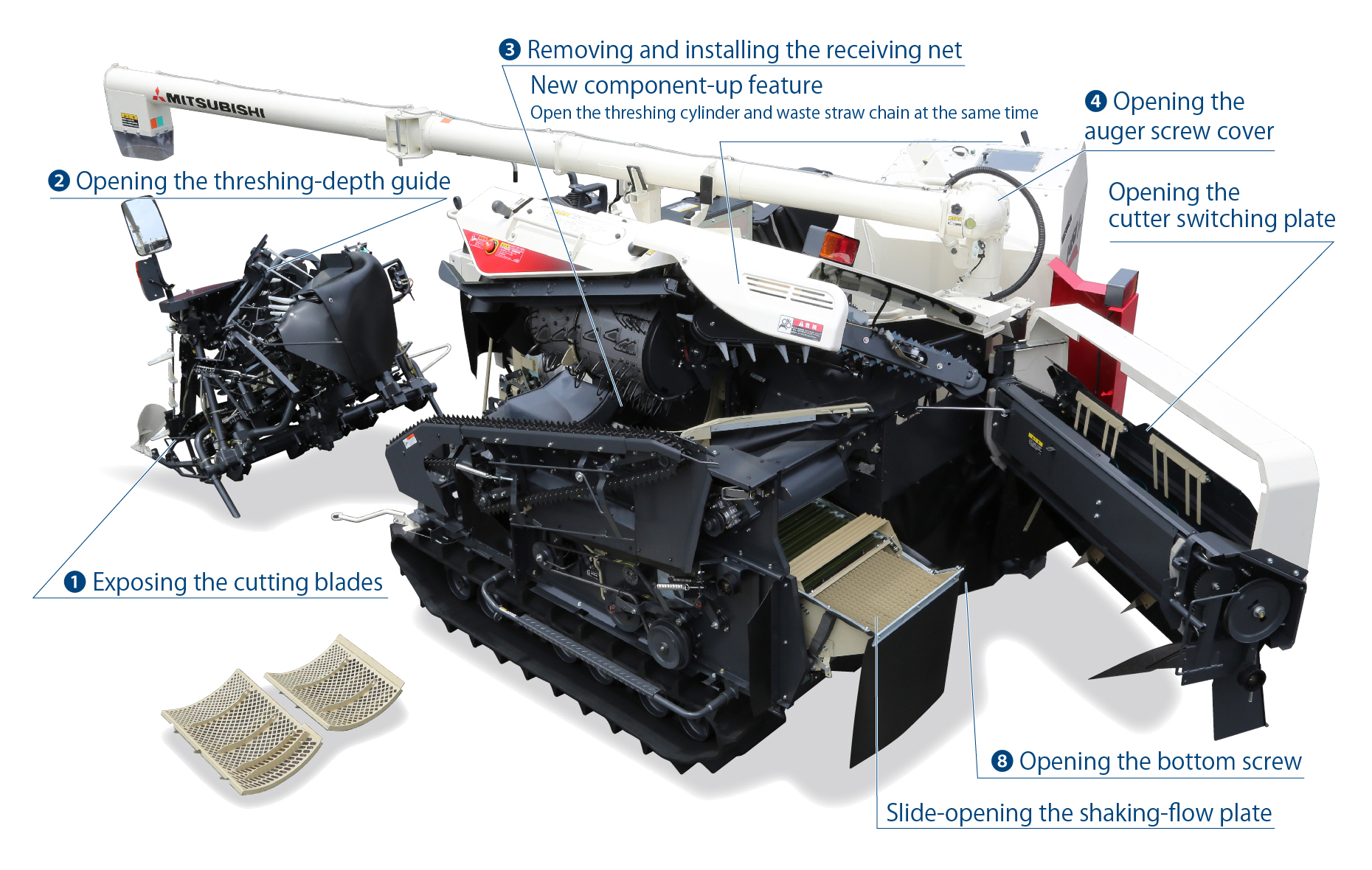

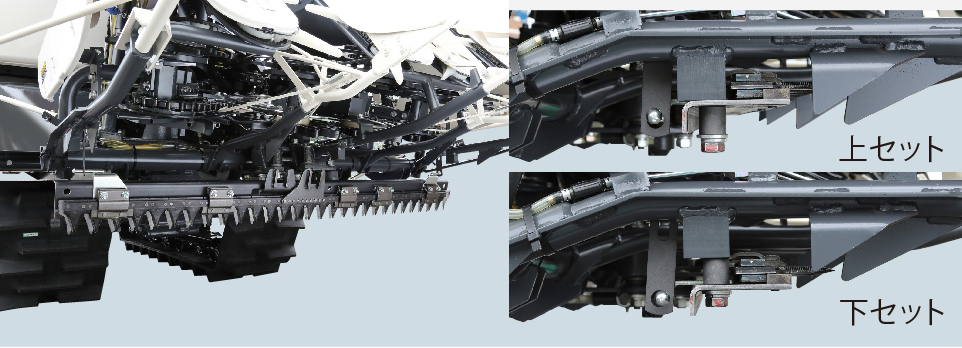

The cutting blades can be exposed to enable maintenance work to be easily performed. Cutting blades can be subject to a two-step adjustment process involving the upper set of blades and lower set of blades.

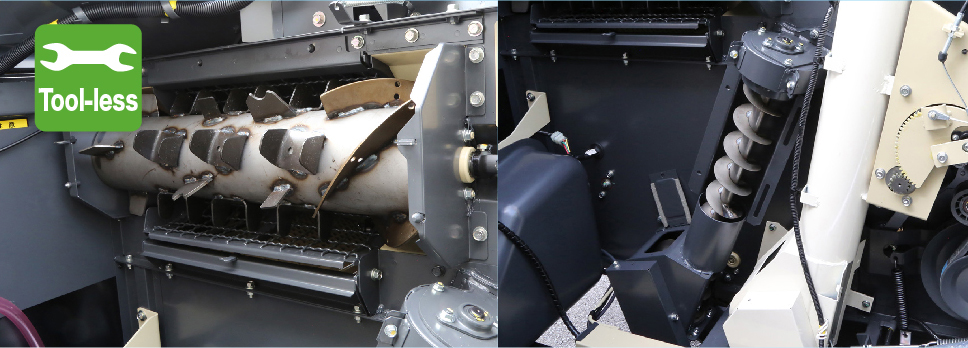

The threshing-depth guide can be easily opened without the use of tools.

The receiving net can be removed and installed without the use of tools and easily cleared of waste straw since the latticework is formed with a die-cutting process.

The auger screw cover can be easily opened and closed without the use of tools.

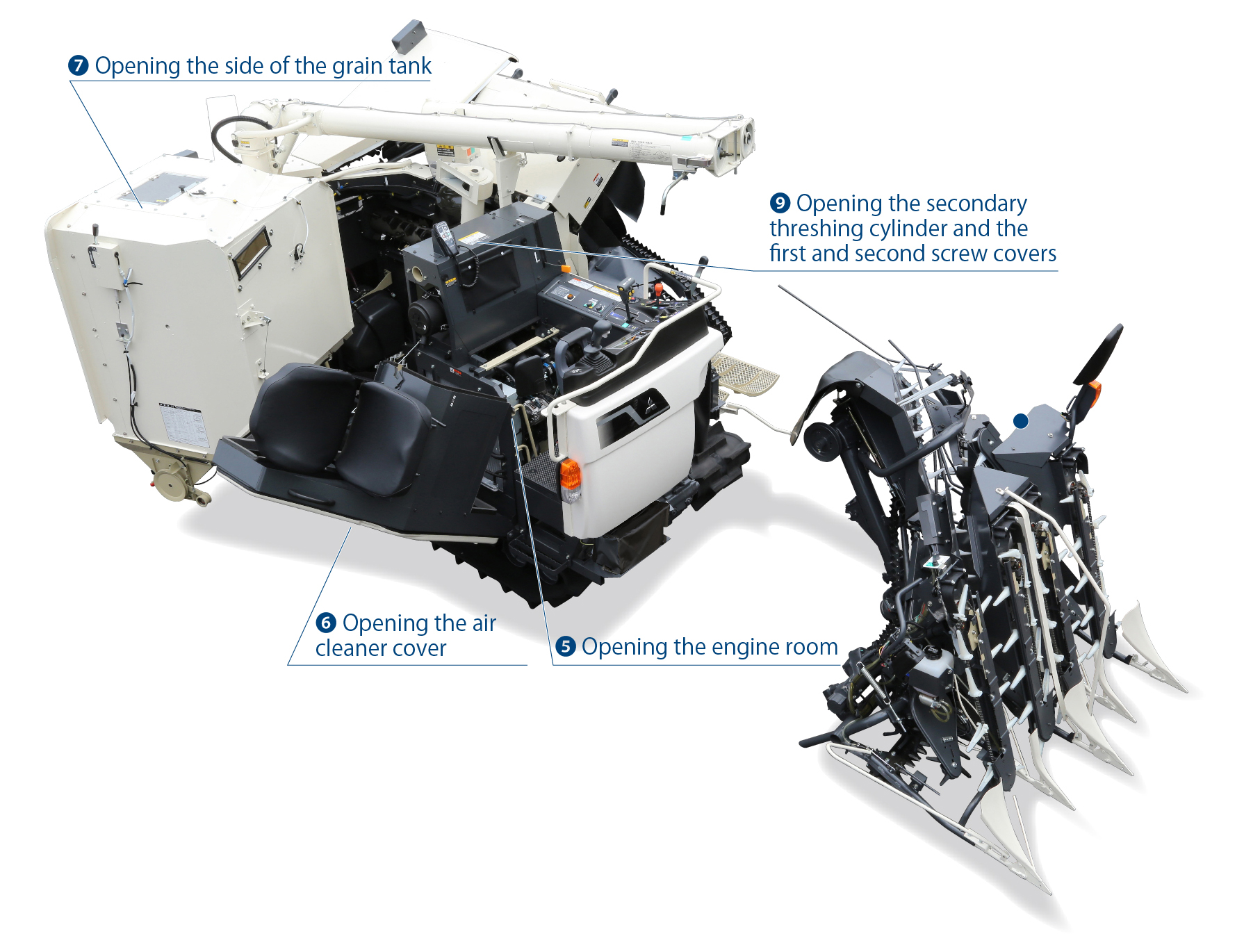

A removal and installation knob is installed on the front of the raising cover. The cover can be removed and installed with ease.

The base plate for the first and second screws can be easily opened.

The first and second screw covers and secondary threshing cylinder cover can be removed and installed without the use of tools.

Scan the QR code affixed near the name plate with your smartphone to access detailed information required for maintenance purposes on your smartphone. *A QR code reader (app) is required. Packet charges incurred when scanning the QR code are assumed by the operator.

- List of error codes

- List of consumables

Engine-related items (such as in regards to the oil filter and air-cleaner element) and list of belts (items relating to tines, cutters, and cutting/scythe blades)

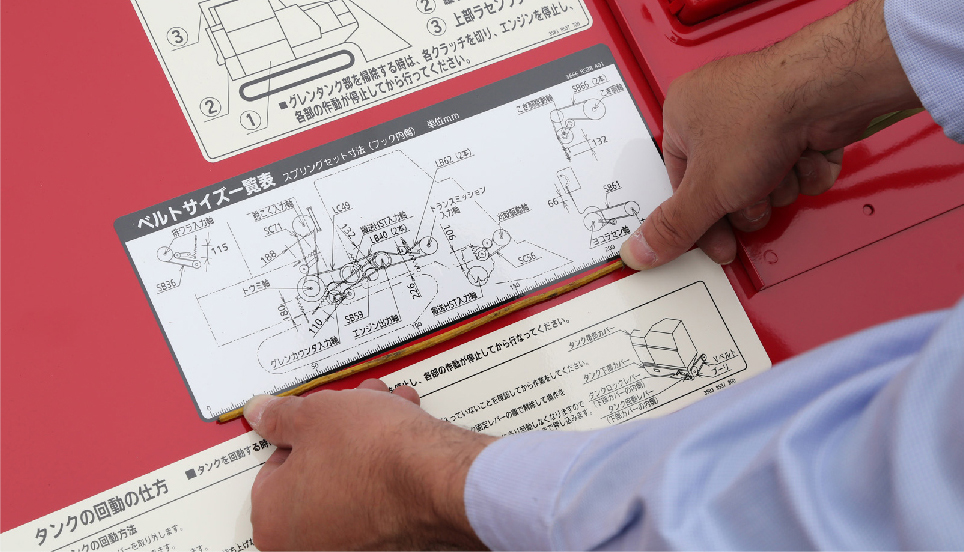

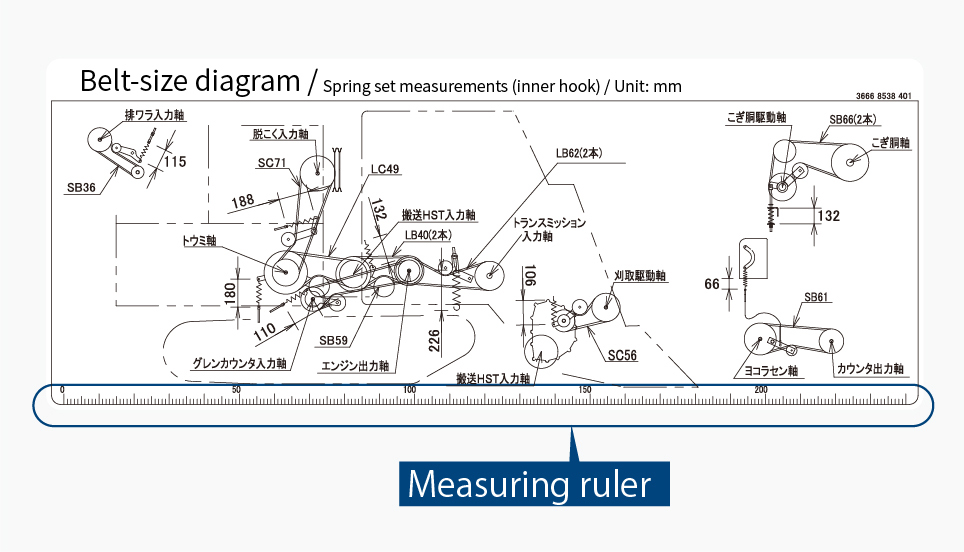

A measuring ruler has been added to a belt size listing label. Even if no measuring tape or other measuring instrument is available in the unlikely event that a problem arises, belt sets and gap measurements can be adjusted and verified.

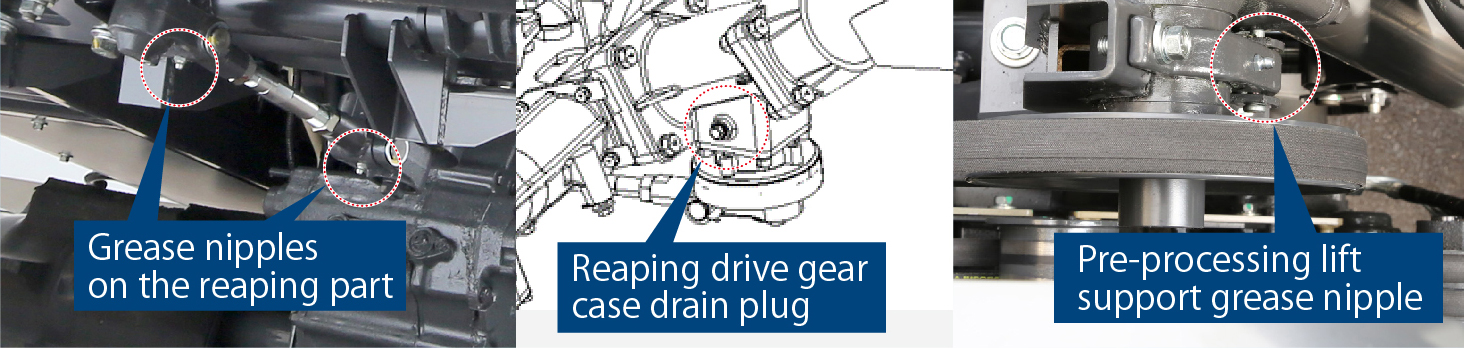

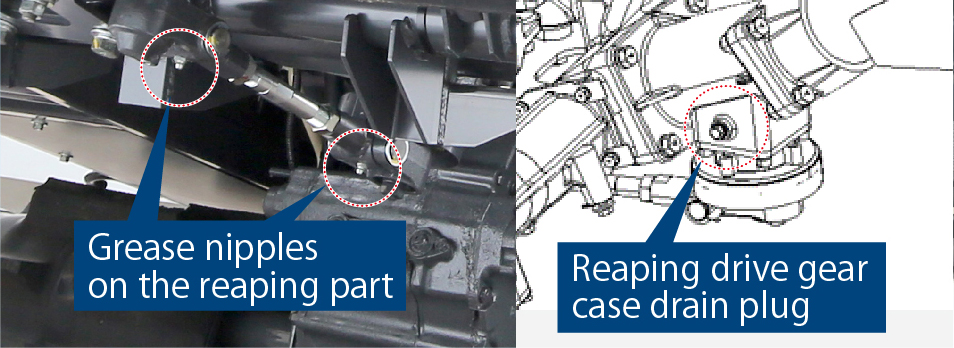

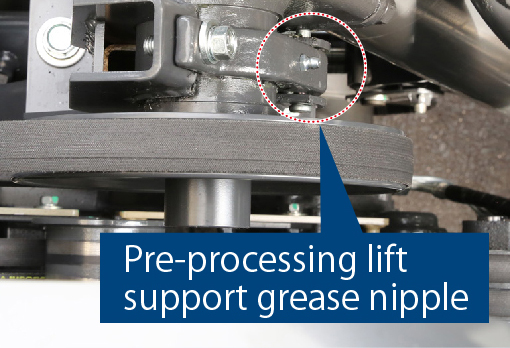

Grease nipples on the reaping part

Grease nipples have been added to the reaping part to facilitate daily inspections and enhance maintenance performance and durability.

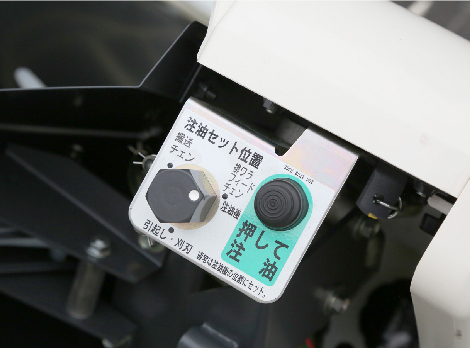

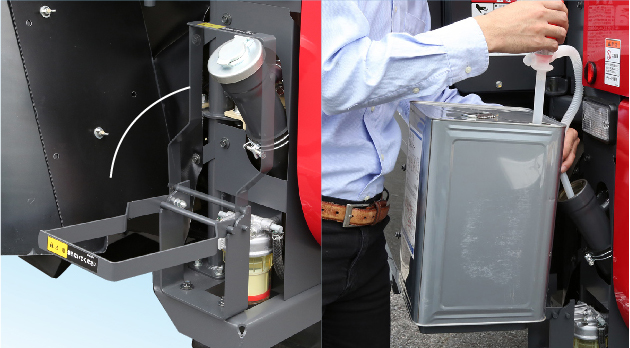

Motorized centralized lubrication

Lubrication can be precisely and simply performed by turning a dial and pressing a button.

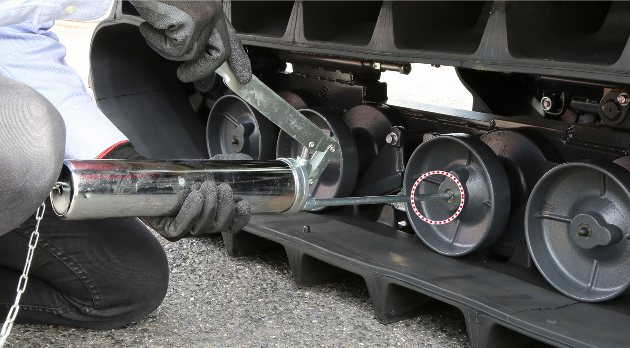

Grease-up rollers of crawler facilitate a daily maintenance routine.

A convenient fueling stand has been mounted to facilitate refueling by giving the operator a place to put the fuel can down.

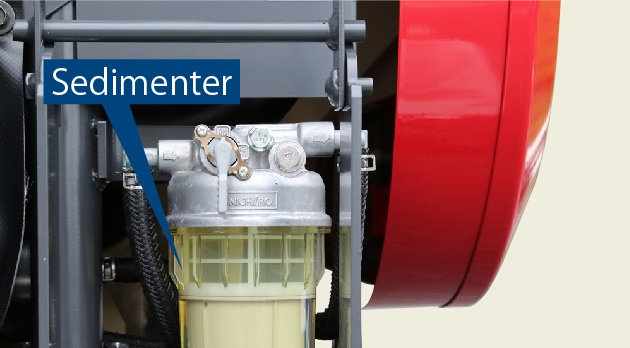

A sedimenter designed to enable the contamination of fuel by water to be visually checked has been mounted near the fuel-inlet cap. This feature allows problems concerning fuel to be prevented.