The cabin offers superior visibility across a wide field of view. The combine is equipped with large work lights as a standard feature of a new design that significantly enhances work performance during the evening hours. Long hours of work can also be undertaken in a relaxed manner by upgraded equipment inside the cabin.

Comprising a camera on the tip of the auger and a back camera, the W Camera System is a standard feature of the cabin specifications for this combine. By configuring the monitor-switching switch to automatic, the angle will automatically switch according to work conditions.

| Power clutch (threshing clutch) |

ON | Normally, the feed from the back camera will be shown. It will switch to the feed from the auger-tip camera during the discharging process. |

| Power clutch (threshing clutch) |

OFF | The feed from the auger-tip camera will be shown when the combine is moving forward or during the discharging process and switch to the back camera when the combine is going in reverse. |

With an inside/outside air-switching air conditioner installed, the work environment has been improved. Comfortable work is supported to the inclusion of a CD player with an FM/AM radio receiver.

A door that slides forwards and backwards is included to enable the combine to be boarded even in tight spaces and effectively used in storage locations.

Align auger discharge positions from a comfortable stance with a wired remote control. A separately sold wireless remote control allows discharging operations to be easily undertaken by an assistant.

A lamp will flash when the grain tank is nearly filled with crop to notify the operator of the state of grain collection. The state of the grain tank can be ascertained by an assistant to facilitate the performance of efficient discharging work.

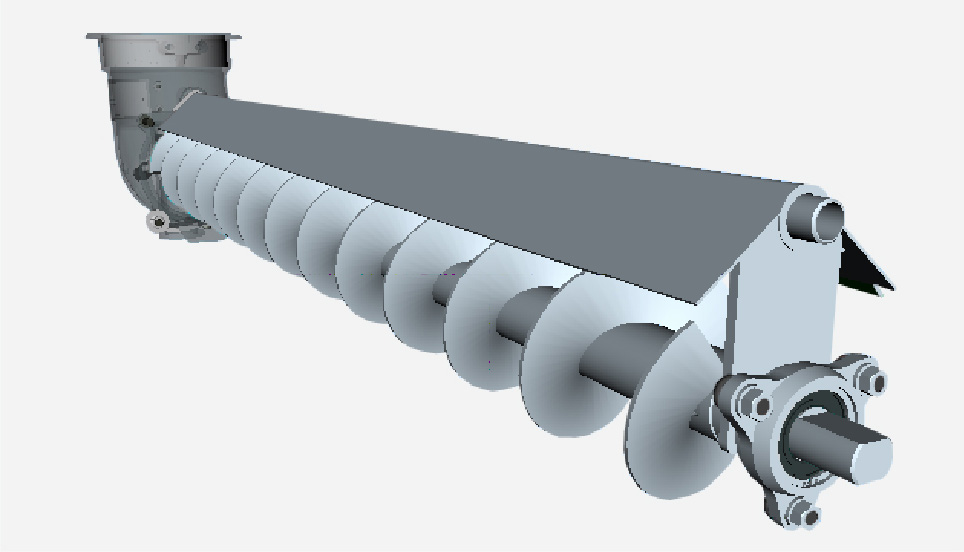

The discharging of unhulled rice is promoted by vibrating the top of the bottom screw in the grain tank.

A large-capacity 1500 L grain tank enables a lower discharge count and can be quickly emptied in approximately 120 seconds. The form of this straight tank allows ridge edges to be reaped with room to spare.

If the grain tank overflows, the engine will be forcefully shut down to prevent secondary problems from occurring.

If the engine speed is insufficient when crop is being discharged, the operator will be notified with an alarm to prevent clogging by crop. *This function is attached to the motorized discharging clutch and auger flaps.

The amount of crop remaining in the grain tank when the discharging of crop is being undertaken is notified with a beep.