The reaping part can be opened without the use of casters. *Excluding ET specifications.

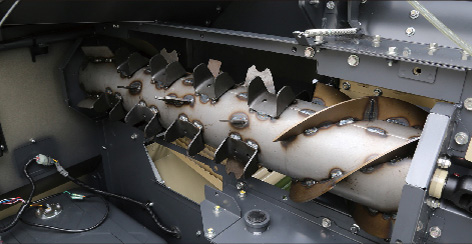

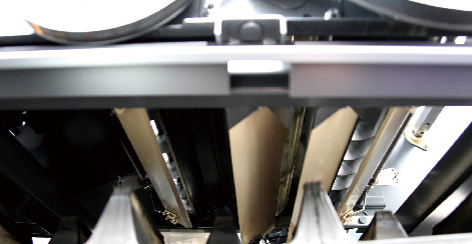

The threshing cylinder and straw-discharging chain can be opened from above.

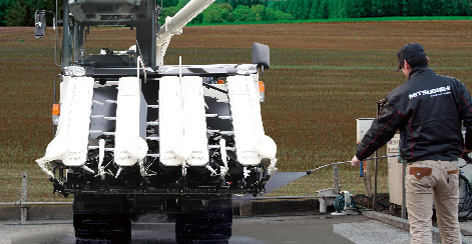

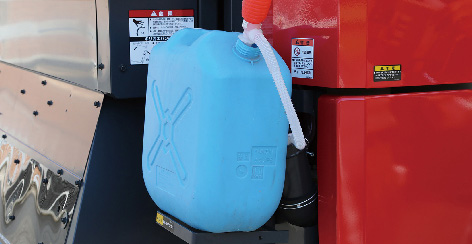

The undercarriage of the combine can be easily washed.

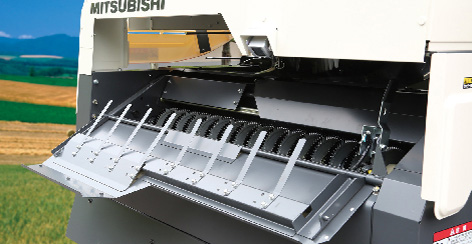

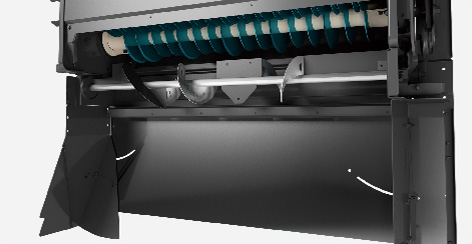

The first and second screw cover and secondary threshing cylinder cover can be removed and installed without the use of tools.

All relevant parts can be lubricated with just the press of a button.

The undercarriage of the combine can be easily washed.

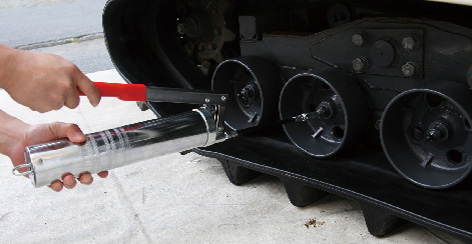

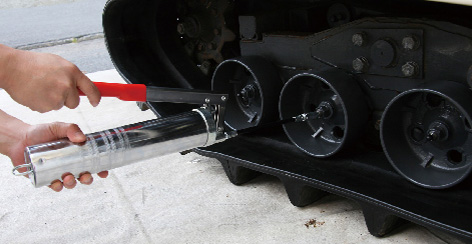

Grease-up rollers of crawler offering superior maintenance performance benefits are utilized.

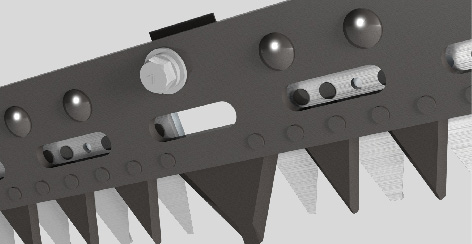

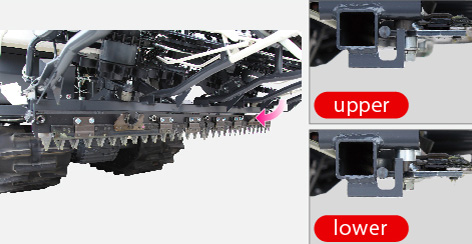

Mud pass-through holes have been added to the back of the cutting blades to increase durability.

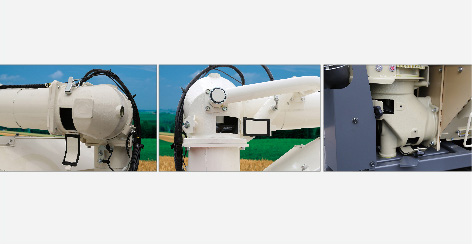

The engine part cover can be opened to handily allow for daily inspections.

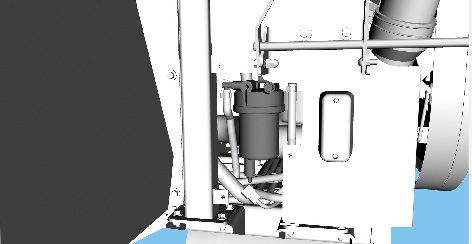

Hydraulic electronic components can be easily checked and any problems that are detected can be promptly addressed.

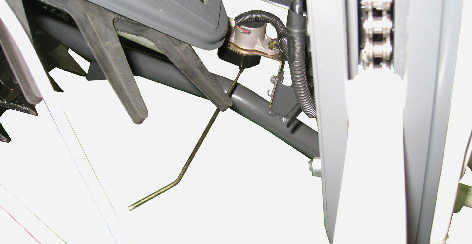

The cutting blades can be exposed to facilitate maintenance. Both the upper set and lower set of cutting blades can be adjusted.

Grease-up rollers of crawler offering superior maintenance performance benefits are utilized.

*Used for the straw-discharging chain and threshing-depth chain.

*Excluding ET specifications

The receiving net can be easily removed and installed without the use of tools. Since the latticework is formed with a die-cutting process, it can also be easily cleared of waste straw.

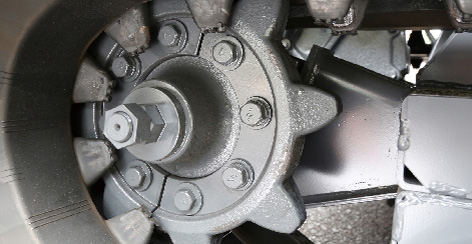

Each sprocket can be easily replaced without having to first remove the crawler.

*Not applicable to V475ET

Grease-up rollers of crawler offering superior maintenance performance benefits are utilized.

The base plate for the first and second screws can be easily opened simply by operating the threshing part lever.

*Excluding ET specifications

| Product name | Model | Comment | V475ET | V475 | V575ET | V575 |

|---|---|---|---|---|---|---|

| Slide knotter | KN-Y463 | Ear and plant base bundle type; with large-ball basket attached. | ○ | ○ | ○ | ○ |

| Bale-standing device | R-KSY60 | ○ | ○ | |||

| Knotter dropper | D-KNVY1 | Mounted on KN-Y463. | ○ | ○ | ||

| Cutter dropper | S-Y60D | Diffusion screw kit (463E-SKIT) required. | ○ | ○ | ○ | ○ |

| Super divider | SP-G563F | One-touch installation and removal, automatic chain tensioner (quad); SP575 kit required. | ○ | ○ | ||

| Super divider | SP-Y60W | One-touch installation and removal, automatic chain tensioner (double); SP575 kit required. | ○ | ○ | ||

| Super divider | SP-463TQ | One-touch installation and removal, automatic chain tensioner (third). | ○ | ○ | ||

| SP575 kit | K-SP575 | Super divider installation kit. | ○ | ○ | ○ | ○ |

| Combine hood | CH-60 | ○ | ○ | ○ | ○ | |

| Short-cutting cutter kit | DMR85S-KIT | Exclusively for M specifications. | ○ | ○ | ||

| Diffusion screw kit | 463E-S-KIT | ○ | ○ | ○ | ○ | |

| Dust control cover kit | DC-VG570 | Non-X specifications (with cabin). | ○ | ○ | ○ | ○ |

| Motorized clutch + auger flap kit | K-Y463DF | Standard equipment for X specifications. | ○ | ○ | ○ | ○ |

| Wireless remote control for auger | K-RCVSVCH | (K-Y463DF) required for non-X specifications. | ○ | ○ | ○ | ○ |

| Driver’s seat centralized lubrication switch kit | K-DCL698 | ○ | ○ | ○ | ○ | |

| Automatic direction kit | Y463-H-KIT | Kit part no. (3606 9750 000). | ○ | ○ | ○ | ○ |

| High-intensity work light (auger tip) | Part no. (1053 7432 000); other parts required. | ○ | ○ | ○ | ○ | |

| High-intensity work light (left of driver’s seat) | Part no. (1053 7432 000); other parts required. Non-X specifications (with cabin). | ○ | ○ | ○ | ○ | |

| Crimped receiving net A (18P) | Part no. (3583 7201 001) | ○ | ○ | ○ | ○ | |

| Crimped receiving net B (18P) | Part no. (3583 7211 001) | ○ | ○ | ○ | ○ | |

| Crimped receiving net A (14P) | Part no. (3583 7294 000) | ○ | ○ | ○ | ○ | |

| Crimped receiving net B (14P) | Part no. (3583 7296 000) | ○ | ○ | ○ | ○ | |

| Cutter blade ASSY | Part no. (3685 8980 000); compatible with the harvesting of wheat (wheat straw cutting performance improved). Cannot be mounted onto a short-cutting cutter. | ○ | ○ | ○ | ○ | |

| Reaping part removal and installation stand (1 unit) | Part no. (3586 8637 000). *2 units required. | ○ | ○ | |||

| Rear weight for oil bath-type tank roller ASSYM | "Part no. (3583 2251 001) Part no. (3544 2861 000); other parts required." |

○ ○ |

○ ○ |

○ ○ |

○ ○ |