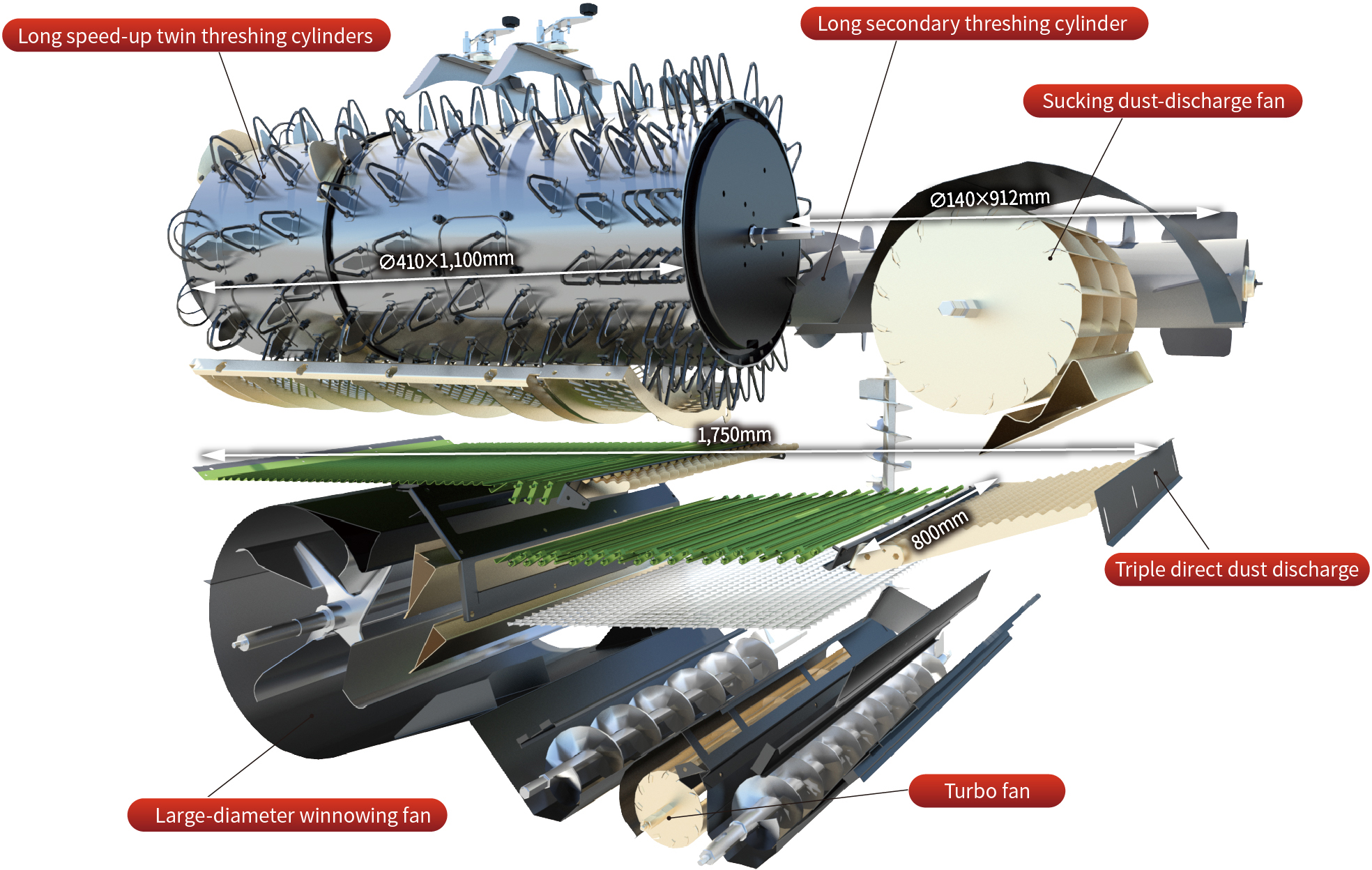

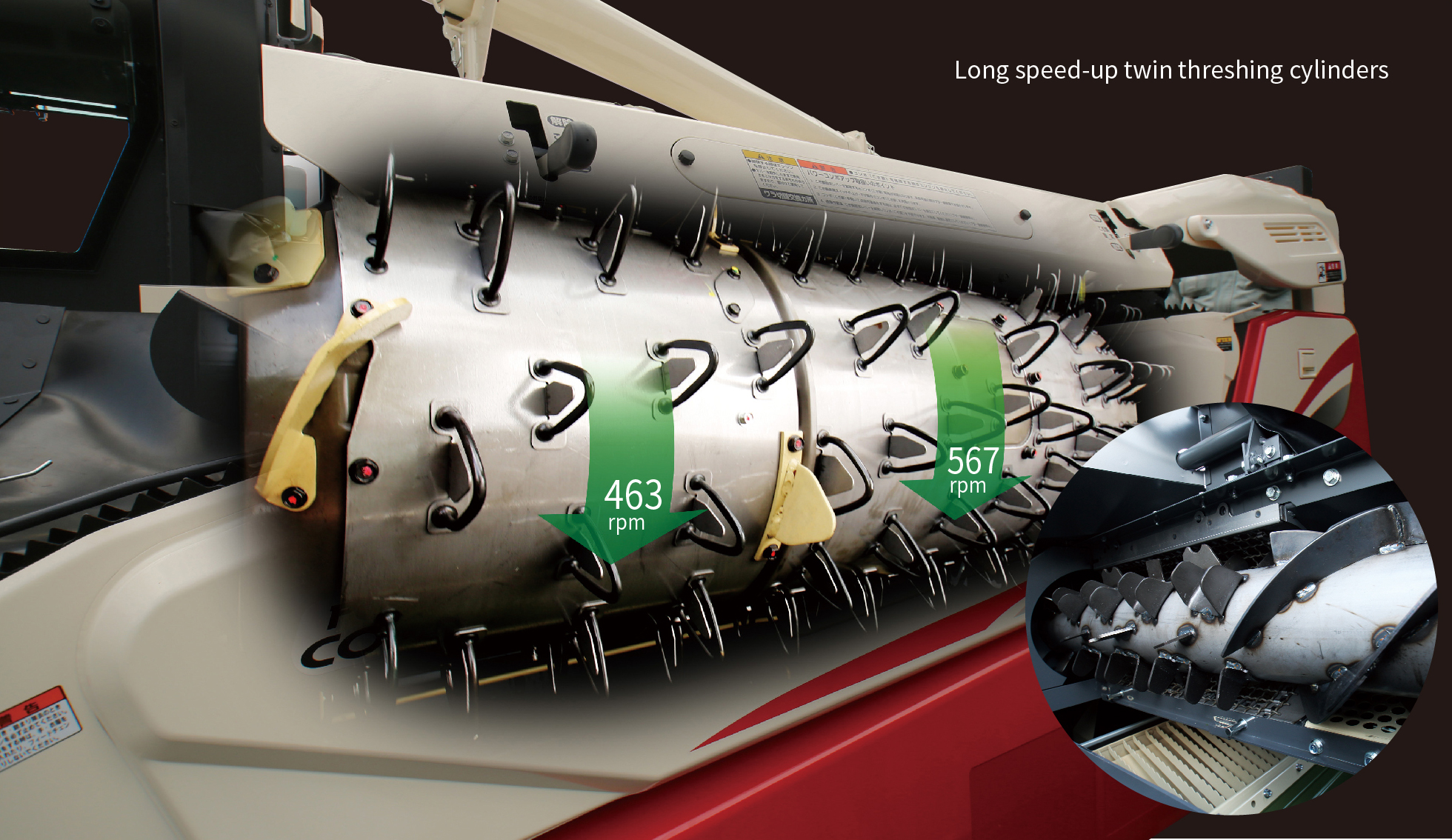

The core part of the threshing system features long speed-up twin threshing cylinders boasting exceptional work efficiency. The forward slow-rotating threshing cylinder gently threshes crop while the rear cylinder rotates quickly to process any rice that remains crop and waste straw. In this way, the speed-up twin threshing cylinders boost capacity by approximately 30 percent over single cylinders of the same size (as found in other models we sell). By also equipping the combine with a 912-millimeter-long secondary threshing cylinder, the processing of waste straw is promoted and high-precision threshing is realized.

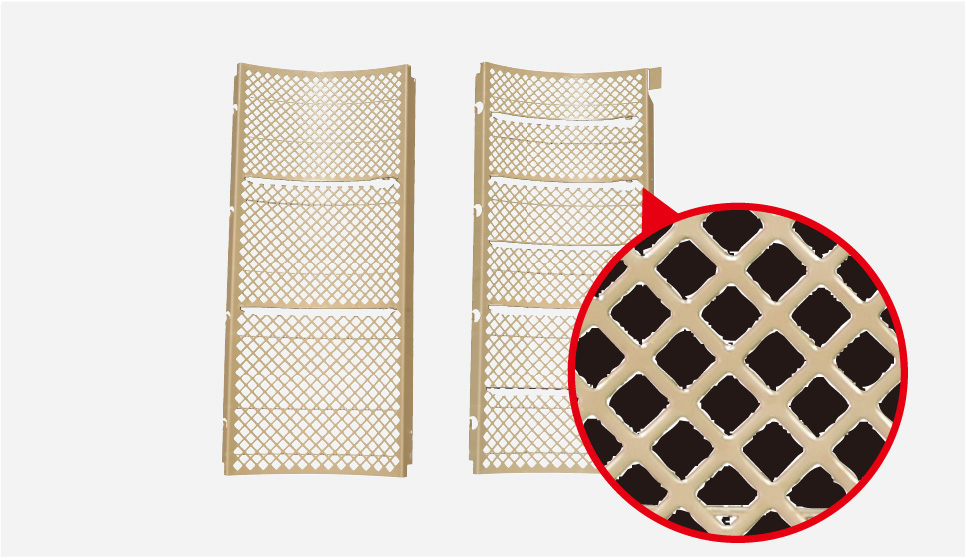

Promotes threshing with Mitsubishi’s original hole shape. With less clogging taking place, this net is also easy to clean.

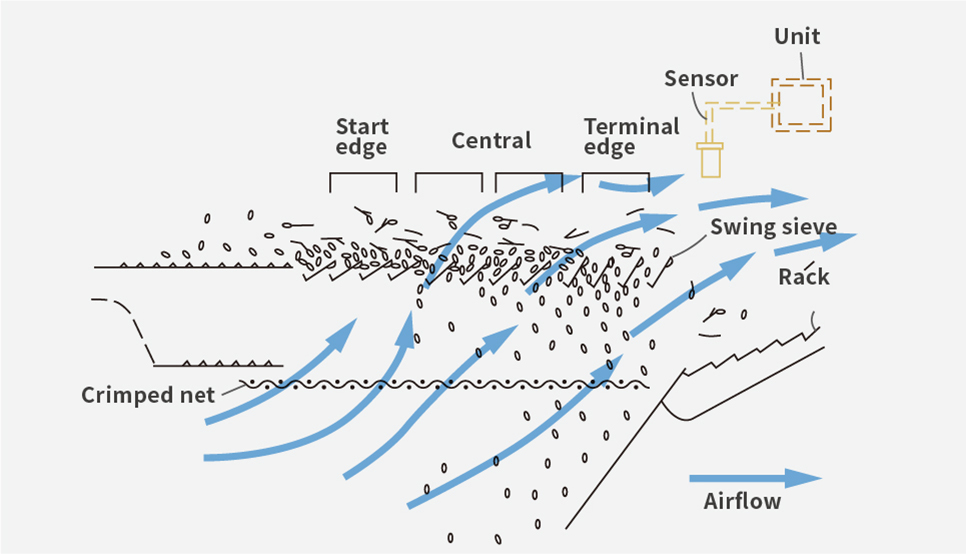

Sorting fins are subject to fully to fully automatic control based on aur-based detection within the threshing process to enable high-precision sorting.

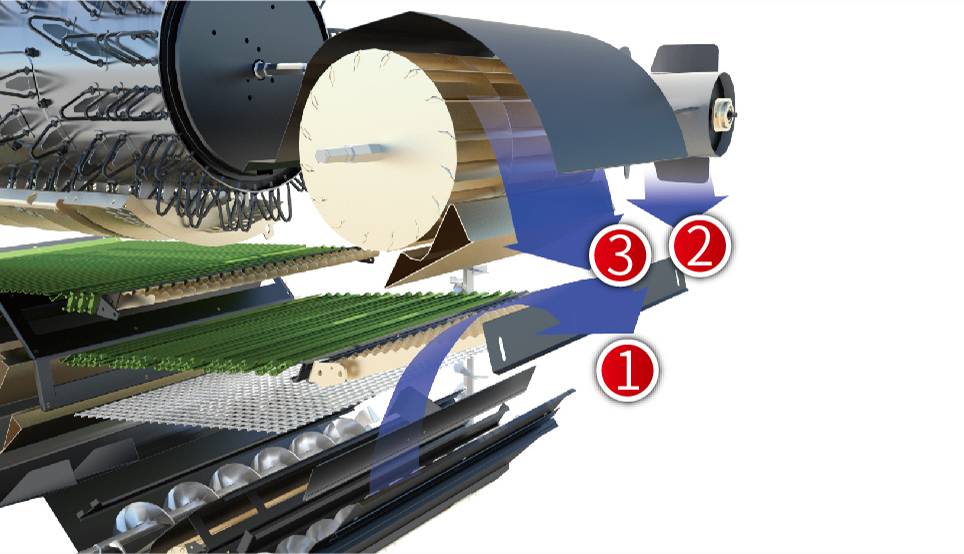

Sorted waste straw is discharged from the following three sites:

❶ Rocking-flow plate, ❷ secondary threshing cylinder, ❸ sucking dust-discharge fan. With little waste retained, exceptional processing capacity is maintained at all times even under harsh conditions.

By feeding airflow for sorting that has been stabilized with a second dedicated airflow for sorting and an airflow for winnowing, sorting precision and processing capacity are enhanced.

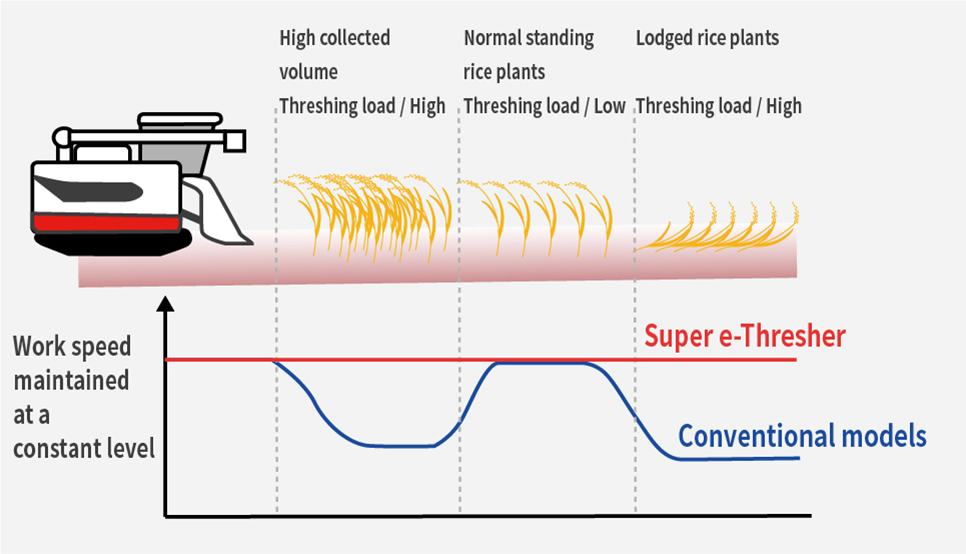

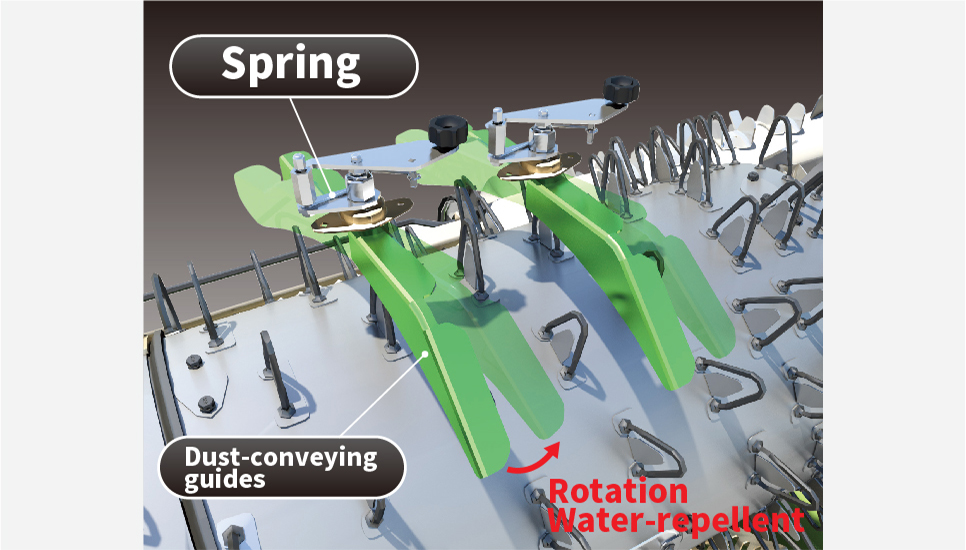

The dust-conveying guides adjust automatically. Stable threshing performance is achieved by optimally maintaining the threshing load in the threshing chamber. Burdensome adjustment operations do not need to be performed.

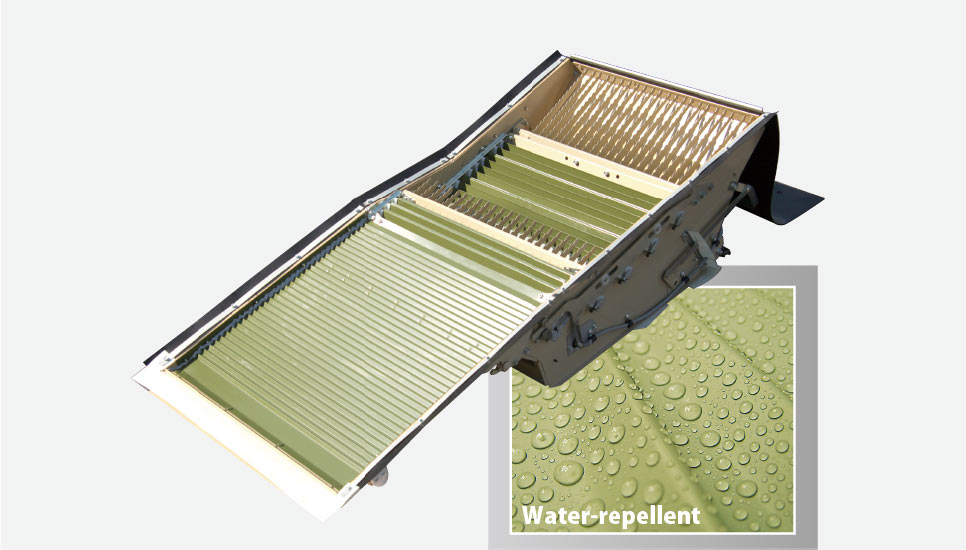

A shaking-flow plate coated in a fluorocarbon resin is used to bolster the slip characteristics and dispersibility of grains and improve adaptability to wet materials and sorting efficiency.