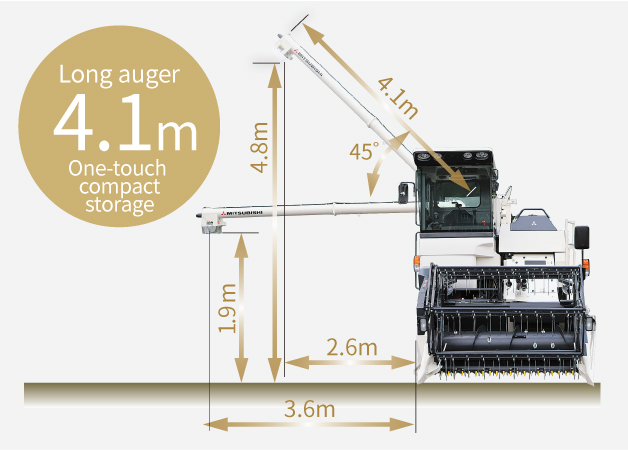

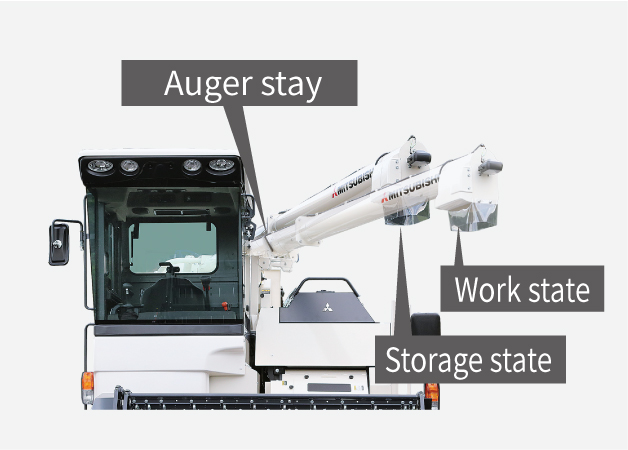

Work performance when discharging with a 4.1-meter long auger is exceptional. For the effect of synergy with an automatic auger-rotation function, discharging work is smooth. The auger can also be easily stored in compact spaces as it can be tucked within the full width of the combine such that extra space is not taken up when moving or storing the combine. If the combine is moved with the auger not yet placed in a storage state, a buzzer will sound and a notification will be displayed on the LCD monitor to prevent problems from being caused by a failure to store the auger.

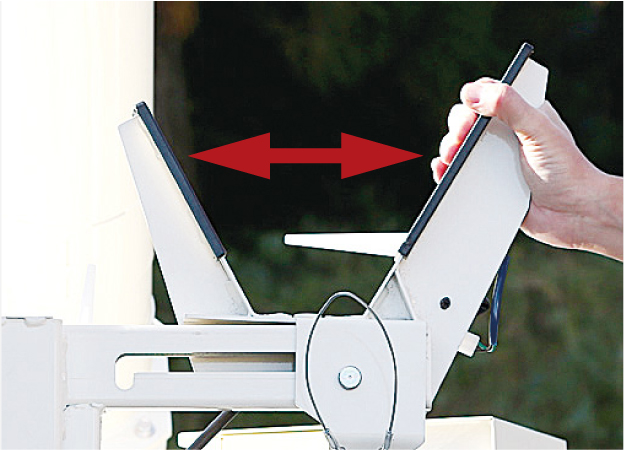

The auger stay can be easily moved with one-touch operations.

*Place the auger in a storage state when traveling on roads or loading the combine onto another vehicle. With the auger stay in a storage state, the reaping part and reel will be subject to restrictions on raising and lowering operations.

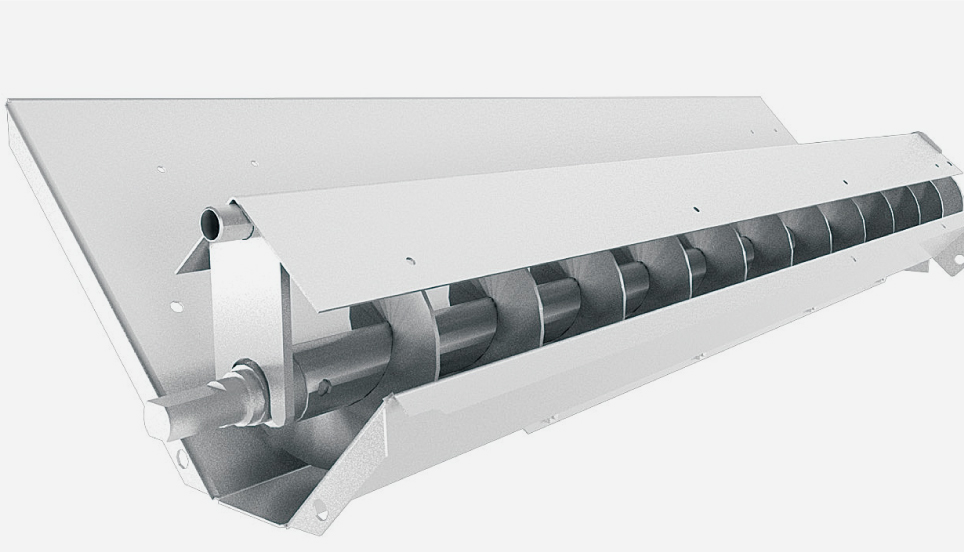

Shake the guide plate above the screw inside the grain tank to prevent bridging, which is liable to occur with wet materials. Smooth discharging over short periods of time can be undertaken.

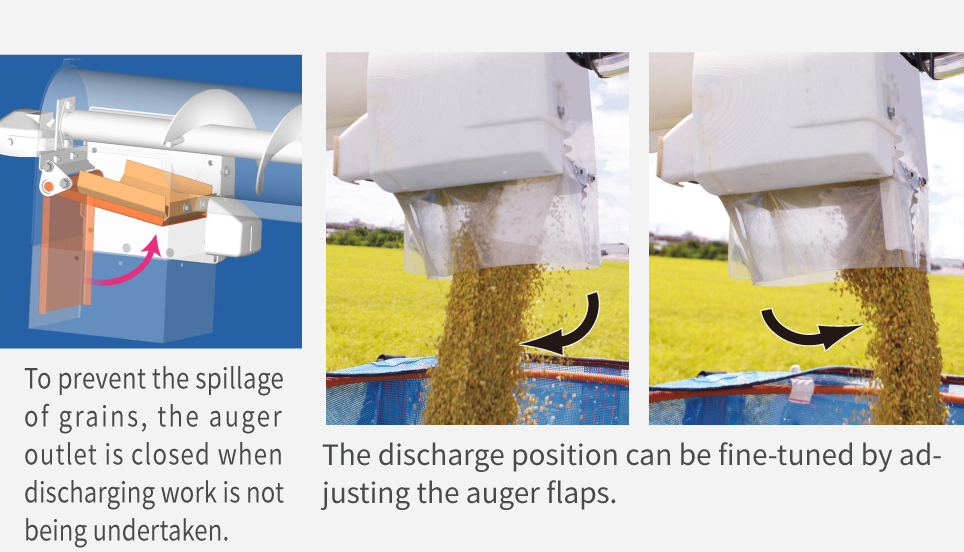

This combine is equipped with convenient flap covers that can be opened or closed to fine-tune the position at which harvested crops are discharged. Efficiently and reliably transfer harvested crops to a container while keeping an eye on the state in which they are being discharged.

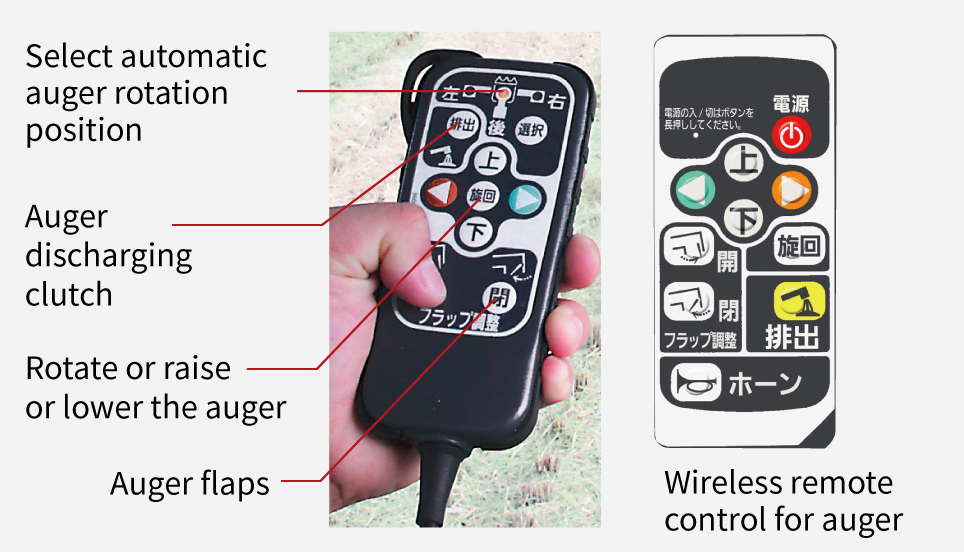

A wired remote control for operating the auger is located behind the seat. Engage in operations while maintaining a comfortable posture and keeping an eye on the state in which crops are being discharged. A wireless remote control is also offered as a separately sold option.

When the grain tank is almost full, a blinking lamp will flash to notify an assistant positioned away from the combine in an easy-to-understand manner. Since it is possible to ascertain the state of grain collection and since coordination with the operator is easily established, discharging work can be efficiently undertaken.

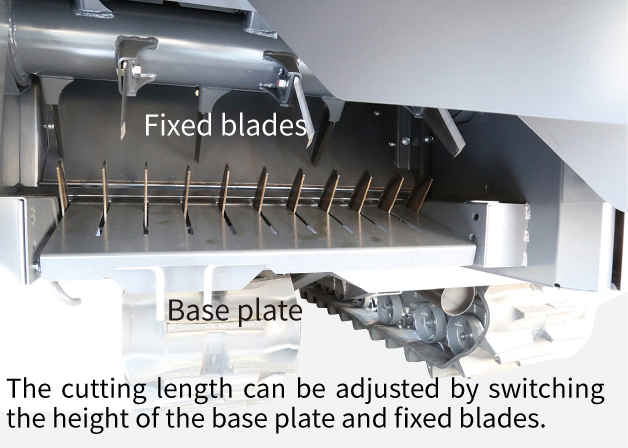

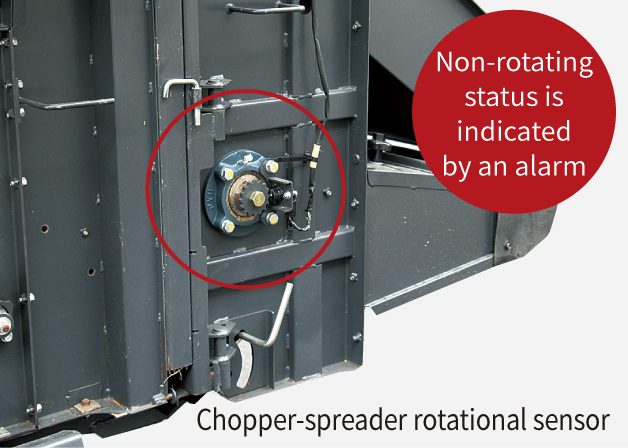

This feature cuts up waste culm and spreads it evenly onto the field. (The extent to which waste culm is cut up can be incrementally adjusted.) Post-harvesting tillage work is rendered easier to undertake. For a rotational sensors that are installed on the combine, warnings and buzzer sounds are issued whenever the rotating blades have stopped rotating. This helps to prevent such problems as clogging caused by forgetting to properly couple the belt after maintenance work has been performed.