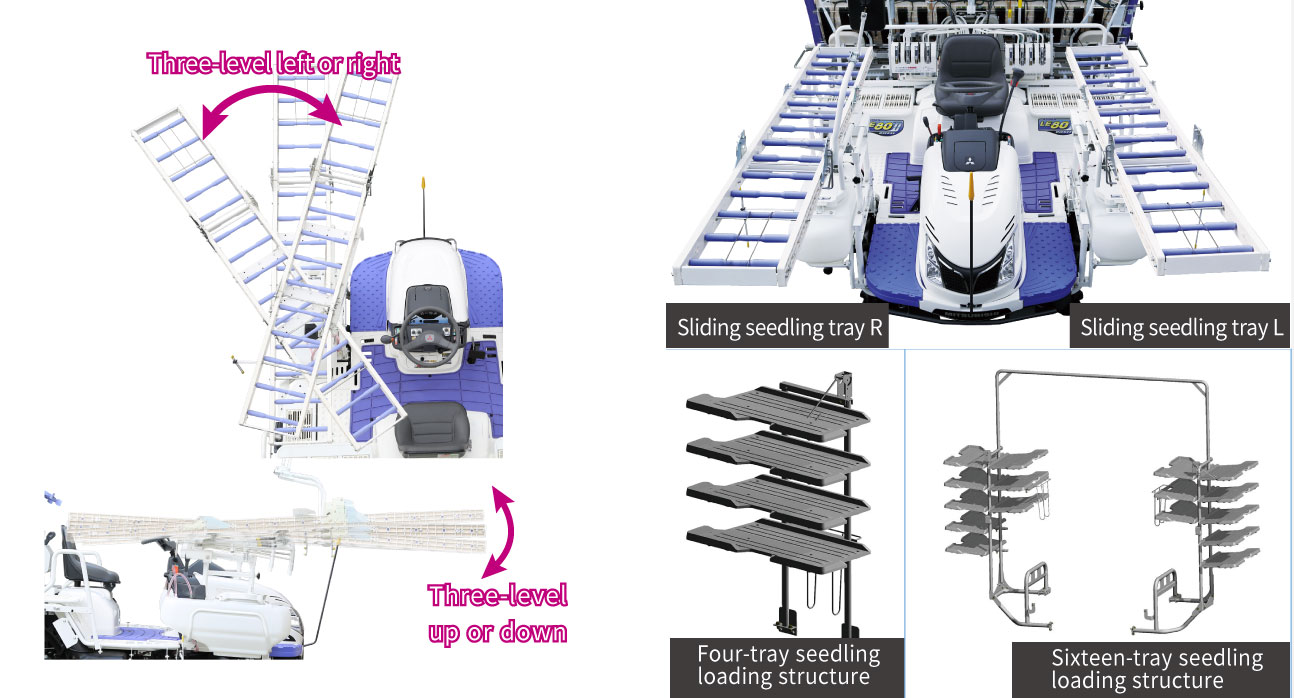

Use convenient sliding seedling trays whose positions can be adjusted in accordance with field to facilitate normally troublesome task of restocking seedlings.

❶ Excellent water-draining caged rotor

❷ A staggered alignment rotor designed to ensure that surface of field is not struck all at once

❸ Stable rotor rotations made possible through system linked to traveling speed of rice transplanter

“Makurakko” function, which helps to generate large laborsaving, more advanced.

Carry out beautiful planting work with high level.

These sliding seedling trays can be rotated up, down, left, or right. Since position can be adjusted according to shape of field or situation in terms of restocking of seedlings, restocking work can be undertaken more expeditiously.

Sliding seedling trays and seedling trays can be freely mixed and matched according to operator’s needs. Two patterns of seedling trays – a four-tray option and a sixteen-tray option – are offered.

Stepping floor that extends from side of engine to area around driver’s seat is fully flat. Floor on side of driver’s seat was also expanded laterally.

A secure support frame also facilitates supplying of seedlings.

High-speed work is enabled thanks to configuration that minimizes pushing aside of water into adjacent rows even in fields with significant amounts of water.

“Makurakko” feature can be activated or deactivated just by pressing a dial switch while remaining seated in the driver’s seat. The basic height will be automatically set through linkage with the planting depth. “Makurakko” height can also be fine-tuned through dial operations in accordance with field conditions.

If planting part is raised while “Makurakko” is being operated, the rotor will automatically stop. If planting part is lowered, rotor will automatically rotate. Mud-splattering from rotor during turns is thus prevented. Driving noise is also rendered quiet for greater comfort.

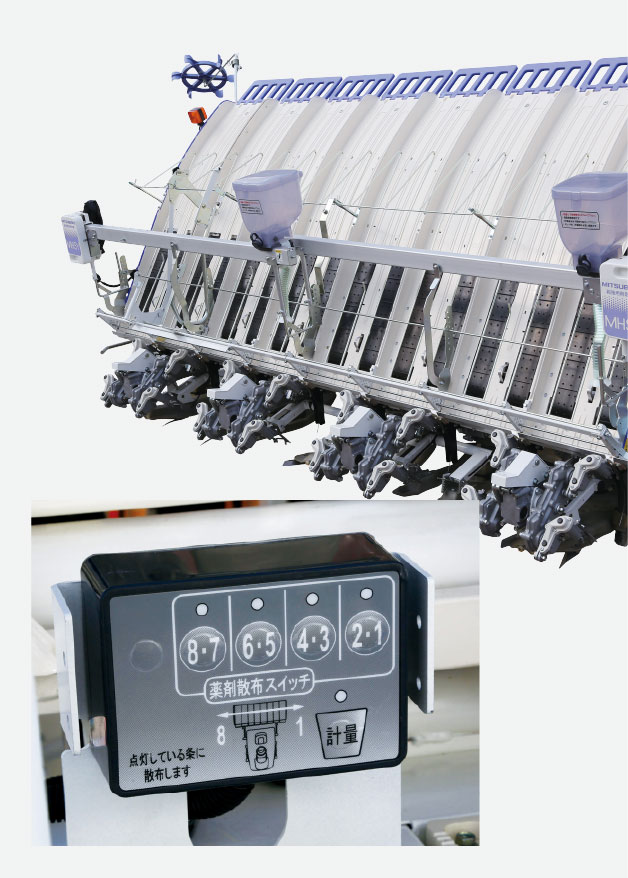

- Achieve laborsaving ……No need to engage in troublesome manual spreading work.

- High-precision spreading is possible……Can spread neatly without unevenness.

- Can reduce quantity of chemical agents used……

Can spread a set amount without squandering material.

- Very easy operations……Once configured, just work as usual!

| Model name | MHSY-E8 |

| Applicable Row | No.8 |

| Type of chemical agent | Agent for application to boxes for raising paddy-rice seedlings |

| Spreading method | Lateral slide-spreading method (linked with longitudinal feeding) |

| Delivery system | Grooved roll system |

| Delivery adjustment system | Roll-based horizontal-width slide system |

| Power | Battery-powered motorized drive |

| Hopper capacity | 7L(3.5×2) |

| Stopping each row clutch | Receptacle |

| Total length x total width x total height (mm) | 250×2610×500 |

| Weight (kg) | 20.5 |

*Cannot be mounted onto 33-centimeter row-width machine (W-type).

*Cannot be used when width of stub is 14 centimeters or less.

*Cannot be mounted together with a chemical agent spreader (MPSR).