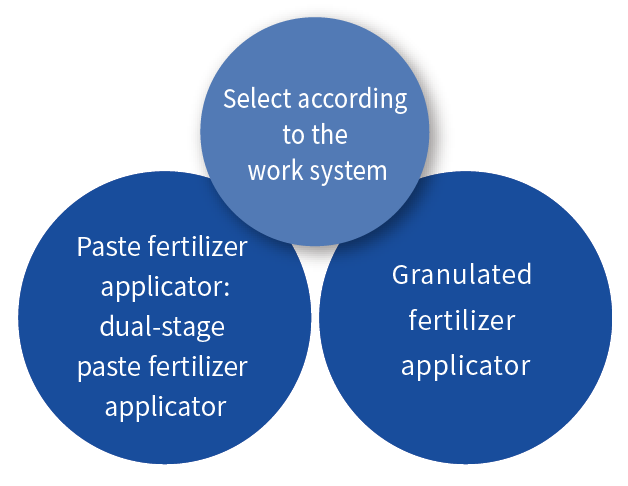

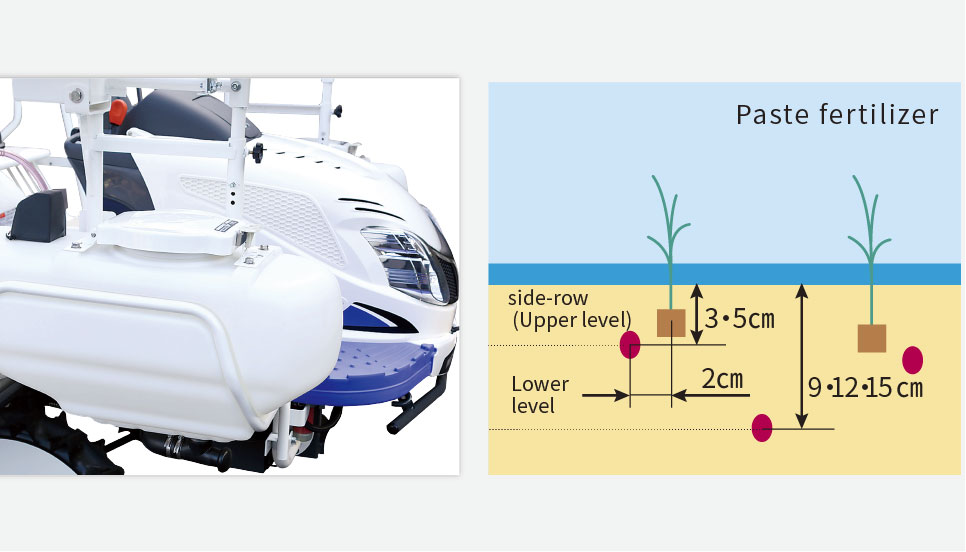

Fertilizer-application system conforms to specifications that enables three different patterns of use: Application of paste fertilizer, dual-stage application of paste fertilizer, and granulated fertilizer.

Fast, reliable fertilizer-application performance can be achieved thanks to high-precision, high-capacity features that are exceedingly user-friendly.

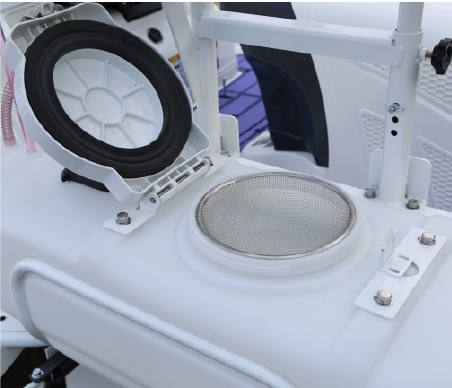

This large-capacity tank reduces frequency at which it needs to be replenished with fresh fertilizer and helps operators engage in uninterrupted work. The cover can be easily opened through a one-touch process. As the tank is mounted externally, rice transplanter itself will sustain less staining by paste in the course of operations. Superior durability was achieved by utilizing rust-proof materials for everything from hooks to the bolts that are used for paste feeder in order to prevent rusting caused by exposure to fertilizer.

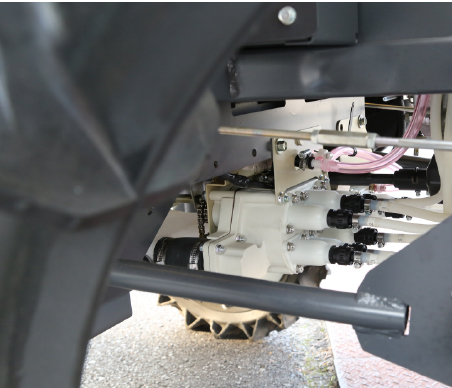

Highly reliable CC (constant-capacity) pump is adopted to steadily supply set volumes of fertilizer. Spiral structure designed to prevent clogging by fertilizer material enables application of fertilizer at high levels of precision and performance of work according to fertilizer-application design.

Left and right indicators will flash once machine is out of fertilizer. Remotely located assistant can also be notified to increase efficiency of any assistance work that is undertaken.

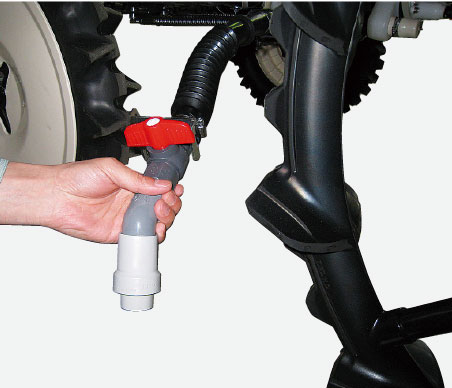

Equipped with a handy paste drain cock that allows you to discharge fertilizer easily without getting your hands dirty.

| 8-row model | ||

| Fertilizer type | Paste | |

| Fertilizer tank capacity (L) | 100(50×2) | |

| Discharging system | C pump | |

|

Upper level |

Upper level Fertilizer-application row | 8 |

| Fertilizer-application system | In-ground side-row fertilizer application | |

| Fertilizer-application position (cm) | 2 to the side of seedlings at depths of 3/5/7 (3 stages) | |

| Discharging range (N∙kg/10 a) | 2.3 to 7.7 {2.1 to 7.0} (12 stages) | |

|

Lower level |

Fertilizer-application row | 4 |

| Fertilizer-application system | In-ground side-row fertilizer application | |

| Fertilizer-application position (cm) | Inter-row mid-point at depths of 9/12/15 (3 stages) | |

| Discharging range (N∙kg/10 a) | 1.1 to 3.9 {1.0 to 3.5} (8 stages) | |

*{ } corresponds to 33 cm

This flip-up hopper can be quickly emptied of any remaining fertilizer by opening outlets on both sides. Catch basin can also be cleaned with ease.

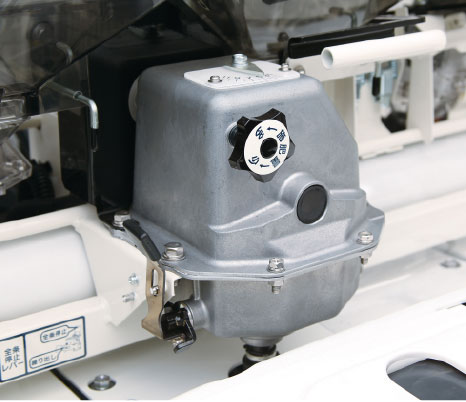

The volume of fertilizer to be applied can be easily adjusted with a single dial. Adjustments between ten and ninety kilograms per tenth of a hectare can be made with a complete seedling count. An all-rows fertilizer application clutch is also provided to enable the drive and blower to be shut-off through a one-touch process whenever the fertilizer is not being applied.

Faulty operations are prevented since the fertilizer application row-stoppage clutch and planting row-stoppage clutch are linked.

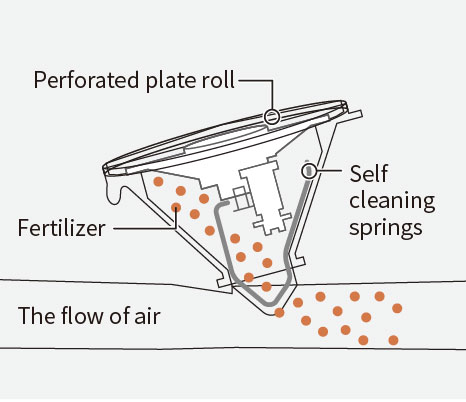

Self-cleaning springs prevent clogging of air-merging parts where granulated fertilizer is susceptible to pooling and facilitates distribution of fertilizer.

Left and right indicators will flash once the unit is out of fertilizer. A remotely located assistant can also be notified to increase the efficiency of any assistance work that is undertaken.

| 8-row model | |

| Fertilizer type | Granulated fertilizer |

| Fertilizer hopper (L) (individual) | 104 (13 L × 8) |

| Feeding system | Perforated plate roll |

| Fertilizer-application row count | 8 |

| Fertilization-application system |

System under which fertilizer is placed in created grooves and covered by soil |

| Fertilizer-application position (cm) | 5 to the side of seedlings at a depth of 4 |

|

Feed volume adjustment range (N∙kg/10 a) 60 seedlings {55 seedlings} |

72(36×2) |

*{ } corresponds to 33 cm

Hood can be fully opened through a one-touch process to enable daily maintenance to be easily performed.

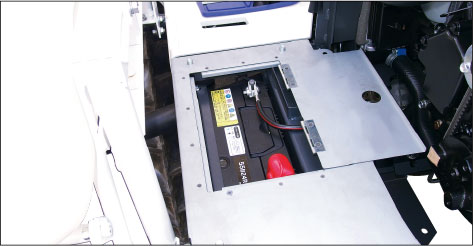

Battery can be recharged without having to be removed. Even pre-season recharging can be smoothly undertaken.

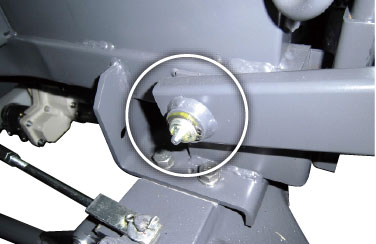

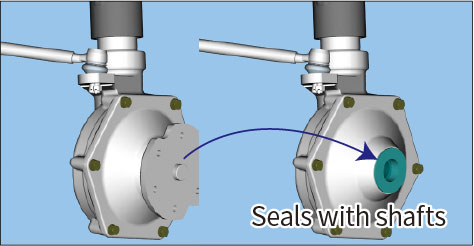

Highly durable seals with shafts are adopted to prevent axle wear.

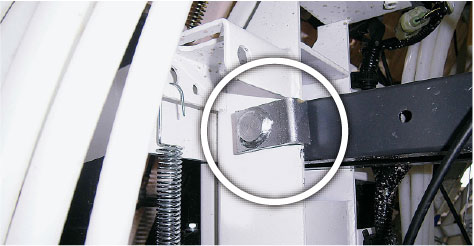

Upper link wear is prevented thanks to use of upper link shaft rotation stoppers.

Key parts have been outfitted with grease nipples and oil filler ports. Since lubrication and greasing can be easily undertaken, machine can be maintained in good condition over a long period of time.