Remove mud, straw waste, and grass, wash out dirt, and wipe off the parts with a dry cloth.

Cover the surface where paint peeled off with repairing paint, and apply grease or oil to the area of the body that rusts easily.

Lubricate rotating parts, sliding parts, and wires to prevent rust.

The air cleaner having dirty elements cannot provide satisfactory performance-during operation.

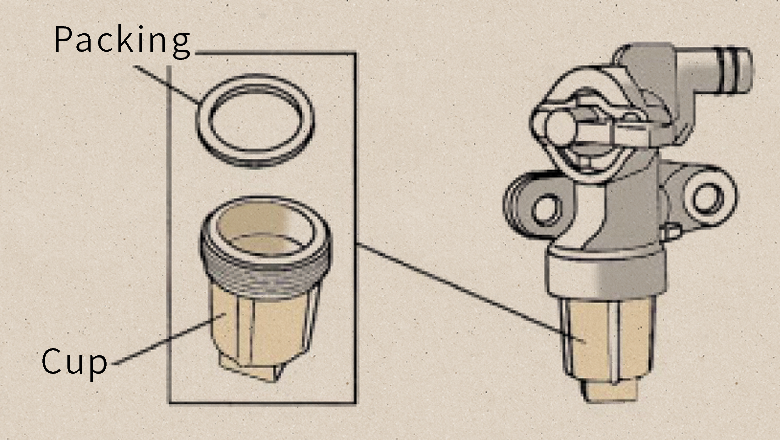

Clean the cup of fuel strainer if water or dust accumulates in it.

Confirm that there is no fuel leakage caused by deterioration or a crack of the fuel hose.

The spark plug also may not work adequately, for example, the engine does not start smoothly if the plug is used for a long time and carbon (soot) builds up on the electrode.

Change the engine oil on a regular basis since it deteriorates after a long time use.

Change it after 30 hours of use for the first time, and after every 50 hours of use from the second time.

*The oil you will be using should be Mitsubishi genuine oil

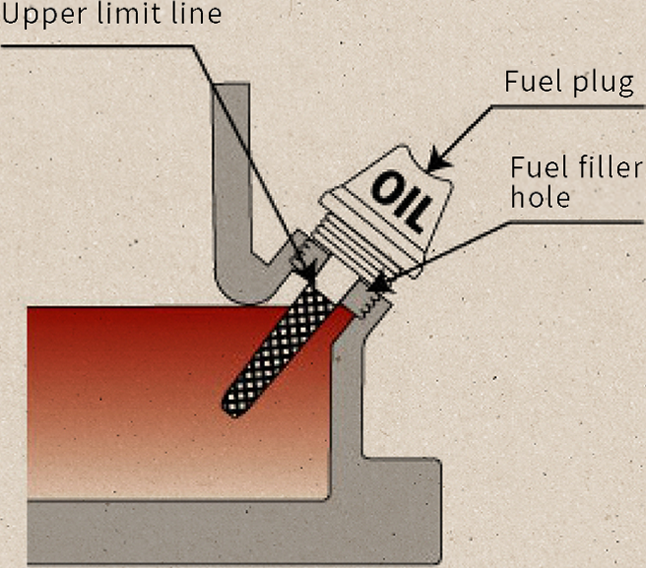

Take off the fuel plug, and check if the oil quantity meets the specified level.

If it is less than the specified level, supply the oil until it reaches the level.

Change the transmission oil on a designated periodic interval.

Each part is properly adjusted when the machine is shipped out; however, readjust the part if wear or losing of elasticity occurs after use or replace it if the condition exceeds the limit of wear to use it appropriately.

As for places to be checked, and details of adjustments, please refer to and follow the instruction manual.

Check for a crack or damage to the tires, and adjust the air pressure.

If the tires are seriously damaged, replace them.

If the machine is not to be used for a month or longer, surely remove gasoline from it. With time, gasoline will deteriorate, which may clog the carburetor and disturb the engine, or lead to a poor driving, so make a point of trying to remove gasoline if the machine will be stored for a long time.

For the storage, wheel lock the tires on a level place to prevent the machine from moving.

A low air pressure might accelerate the deterioration of the tires, so if such is a case, supply the air up to the specified level.

When putting a seat cover on the machine, do so after the engine sufficiently cooling down.

If covering while the engine is still hot, it might be the cause of a fire.

The distributor staffed by agricultural mechanics will provide good after-sales service, such as maintenance and replacement of consumables.

You can also seek or obtain various advice or information there, so we recommend that you purchase the machine in a distributor of agricultural machinery.